2025-06-07 hits:0 source:corten steel fabricators

In smart health monitoring devices, the accuracy of the measurement results is of paramount importance, and aluminum die - castings can have a substantial impact on this aspect through their structural integrity, dimensional stability, and electromagnetic compatibility.

The structural integrity of aluminum die - castings is crucial for ensuring the accuracy of smart health monitoring devices. These devices often contain sensitive sensors and electronic components that need to be precisely positioned and protected. A well - designed and properly manufactured aluminum die - casting provides a robust and stable housing that can withstand external forces, vibrations, and impacts without deforming or damaging the internal components. For example, in a heart rate monitor, any deformation of the housing due to improper die - casting or external stress could misalign the optical sensors used for measuring blood flow, leading to inaccurate heart rate readings. By maintaining its structural integrity, the aluminum die - casting ensures that the sensors remain in their optimal positions, enabling accurate data collection.

Dimensional stability is another key factor. Aluminum die - castings with high - precision dimensions are essential for proper assembly of the various components within smart health monitoring devices. Tight tolerances during the die - casting process ensure that parts fit together accurately, preventing any gaps or misalignments that could affect the functionality of the sensors. For instance, in a blood pressure monitor, the precise fit of the pressure - sensing components within the aluminum - cast housing is critical for obtaining accurate pressure measurements. Any deviation in dimensions could lead to incorrect pressure transmission or sensor calibration, resulting in inaccurate blood pressure readings.

Electromagnetic compatibility (EMC) is also an important consideration for aluminum die - castings in smart health monitoring devices. Aluminum, with its good electrical conductivity, can be used to shield the internal electronic components from external electromagnetic interference. A properly designed aluminum die - casting housing can act as a Faraday cage, preventing electromagnetic waves from interfering with the operation of the sensors and circuits. This shielding effect is vital for maintaining the accuracy of the monitoring device, especially in environments with high levels of electromagnetic radiation, such as near power lines or electronic equipment. By ensuring structural integrity, dimensional stability, and electromagnetic compatibility, aluminum die - castings play a crucial role in enhancing the accuracy of smart health monitoring devices, enabling reliable and precise health data collection for better user health management.

Read recommendations:

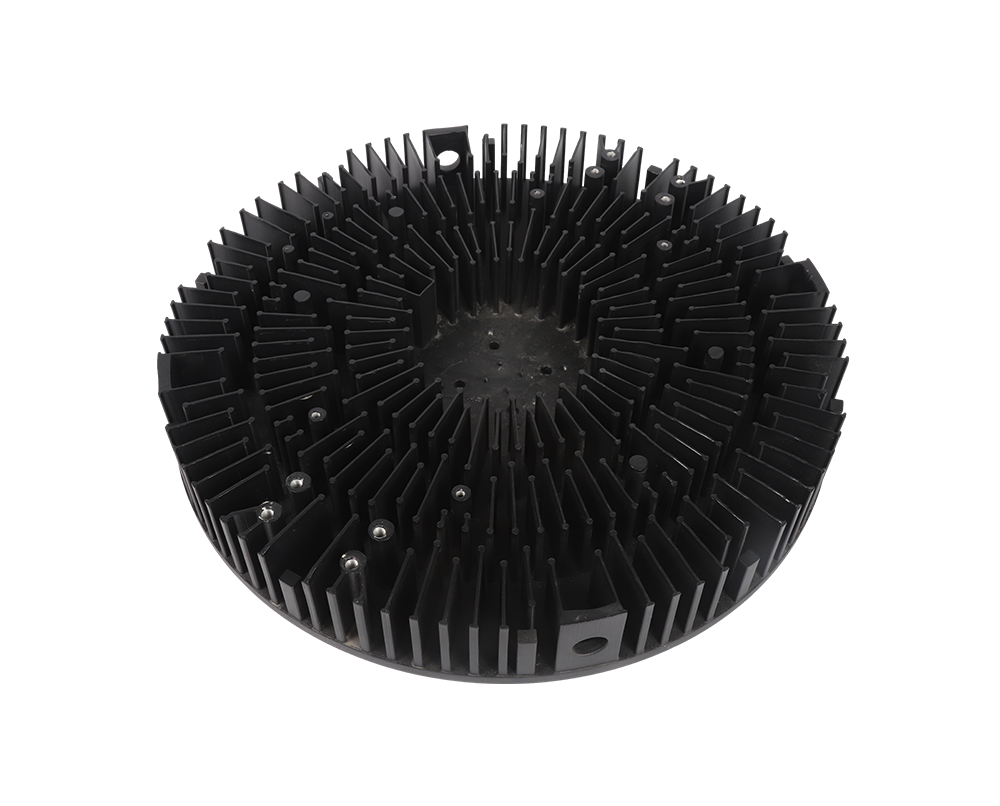

LED Cold Forged Downlight Radiator