2025-07-12 hits:0 source:corten steel fabricators

High-end artistic works, including sculptural elements, decorative artifacts, and limited-edition art pieces, leverage alloy die casting to transform creative visions into tangible, durable art. This method allows artists and designers to realize complex forms that would be difficult or impossible to achieve with traditional techniques like forging or machining.

Alloys chosen for artistic die casting balance aesthetic appeal and structural feasibility. Bronze alloys, with their rich, patina-developing surface, are a popular choice, evoking classical art traditions. Aluminum alloys, often anodized in custom colors, offer a modern, sleek look suitable for contemporary art. Die casting enables the reproduction of intricate details—from fine textures to delicate filigree—capturing the artist’s intent with remarkable accuracy.

The process is highly collaborative, with artists working closely with die casters to refine molds. Investment casting, a form of die casting suitable for complex art pieces, uses wax patterns to create ceramic molds, allowing for one-of-a-kind or limited-run castings. Post-casting, artists may apply patinas, polish selectively, or add other materials (e.g., stone, glass) to enhance the artwork’s visual impact. Unlike mass-produced items, high-end artistic die castings prioritize uniqueness; even in editions, slight variations are celebrated as part of the art’s character. The durability of metal alloys ensures these works can withstand exhibition and handling, preserving their beauty for generations.

Read recommendations:

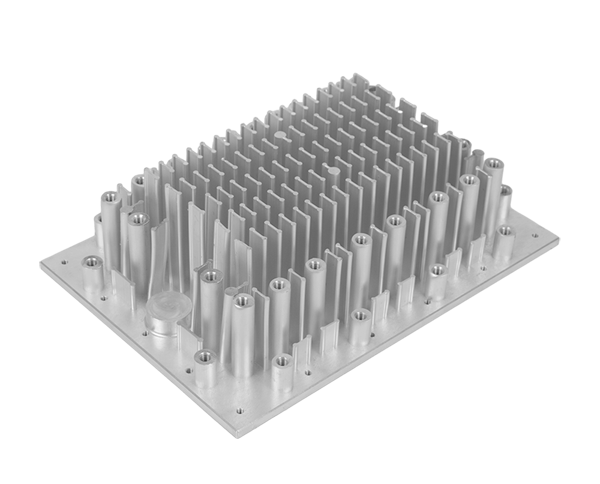

LED Cold Forged Downlight Radiator