2025-06-06 hits:0 source:corten steel fabricators

Alloy die - casting is a vital manufacturing technique in the production of kitchen appliances, enabling the creation of components with high precision, durability, and functionality. The use of suitable alloys and advanced die - casting processes is essential for meeting the specific demands of kitchen appliances.

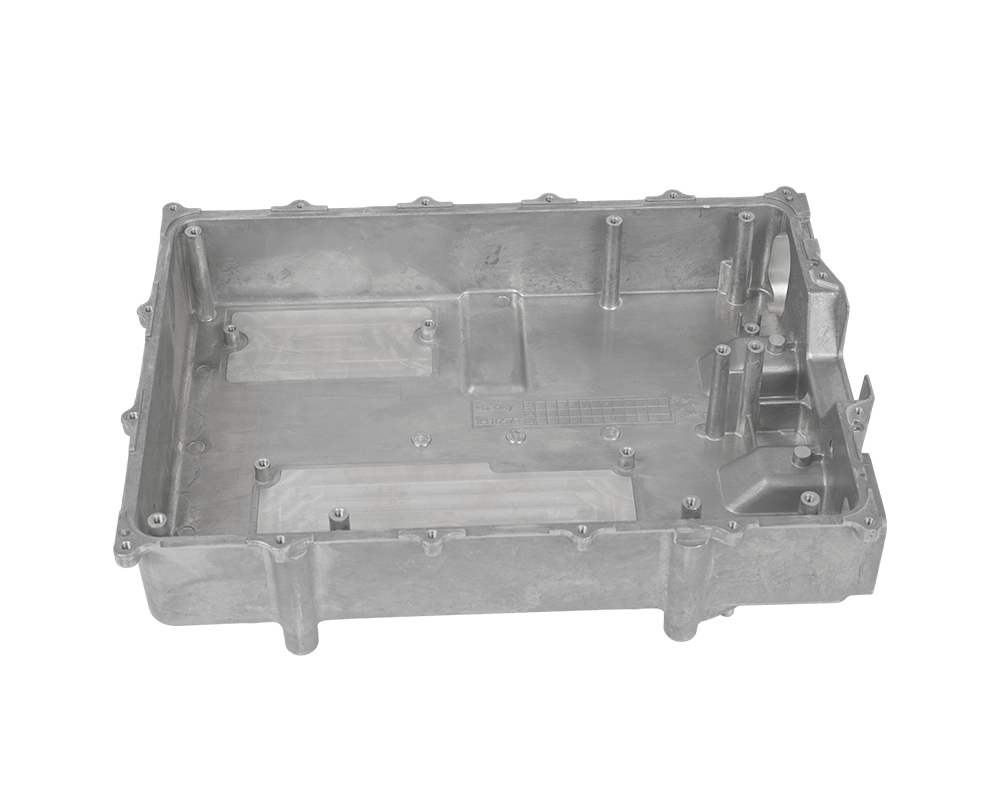

For kitchen appliances, materials such as aluminum alloys and magnesium alloys are commonly used in die - casting. Aluminum alloys are highly preferred due to their excellent thermal conductivity, which is crucial for components like heat sinks in kitchen appliances. Good thermal conductivity allows for efficient heat dissipation, ensuring the normal operation and longevity of electrical components within the appliances. Moreover, aluminum alloys are lightweight, reducing the overall weight of the appliances, making them more portable and user - friendly. They also offer good corrosion resistance, which is important as kitchen appliances are often exposed to moisture, steam, and various food residues. This corrosion resistance helps maintain the integrity and appearance of the components over time.

Magnesium alloys are also increasingly used in kitchen appliance die - casting. They have an extremely high strength - to - weight ratio, making the components made from them both strong and lightweight. This property is beneficial for reducing the energy consumption of the appliances during operation. Additionally, magnesium alloys can be easily machined and surface - treated, allowing for the creation of components with complex geometries and attractive surface finishes.

The die - casting process for kitchen appliances requires strict quality control. During the design stage, engineers need to consider factors such as the mechanical strength, heat resistance, and dimensional accuracy required for different components. The mold design must be optimized to ensure smooth alloy flow and proper filling of the mold cavity, minimizing the occurrence of casting defects such as porosity and shrinkage. After casting, the components undergo a series of inspections, including non - destructive testing methods like X - ray inspection and ultrasonic testing, to detect any internal defects. Surface treatment processes, such as powder coating or anodizing, are then applied to enhance the corrosion resistance and aesthetic appeal of the components.

In the highly competitive kitchen appliance market, the quality and performance of components directly impact the reputation and competitiveness of products. Alloy die - casting technology, with its ability to produce high - quality components efficiently, plays a key role in ensuring that kitchen appliances meet the expectations of consumers in terms of functionality, durability, and appearance.

Read recommendations:

Large Aluminum Cold Forged Pin Fin Radiator

large extruded aluminum enclosure

precision metal stamping manufacturer

What are the four types of heat treatments for processing aluminum alloy die-casting parts