2025-07-15 hits:0 source:corten steel fabricators

Aluminum castings have become indispensable in new energy vehicles (NEVs), serving as foundational components that enable the lightweighting, efficiency, and structural performance required for electric and hybrid propulsion systems. As NEVs prioritize energy efficiency to extend range, aluminum’s low density—approximately 2.7 g/cm³, compared to 7.8 g/cm³ for steel—reduces vehicle weight by up to 30%, directly improving battery life and reducing energy consumption.

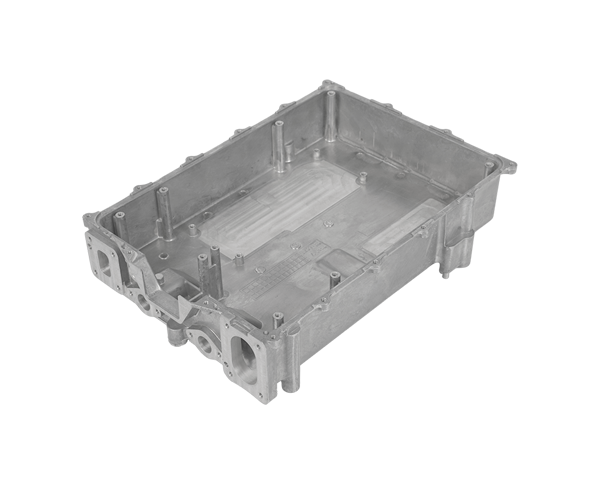

One of the most critical applications is in battery enclosures, which protect the lithium-ion battery pack from impact, moisture, and thermal extremes. Aluminum castings for battery enclosures are often produced using high-pressure die casting, allowing for complex geometries with integrated cooling channels that regulate battery temperature—essential for maintaining performance and safety. Alloys like A356, with good castability and high strength after heat treatment, are preferred for this application, ensuring the enclosure can withstand crash forces while remaining lightweight.

Electric motor housings are another key aluminum casting in NEVs. These components must dissipate heat generated by the motor during operation to prevent overheating and efficiency loss. Aluminum’s excellent thermal conductivity, combined with die casting’s ability to create intricate cooling fins and passages, makes it ideal for this role. For example, permanent magnet motor housings often feature die-cast aluminum designs that integrate heat sinks, eliminating the need for separate cooling systems and reducing assembly complexity.

Chassis components, including subframes, suspension brackets, and steering knuckles, also rely on aluminum castings. These parts require high strength and dimensional accuracy to ensure vehicle stability and safety. Advanced casting techniques like squeeze casting, which applies pressure during solidification, enhance the mechanical properties of these components, making them suitable for load-bearing applications.

Moreover, aluminum castings contribute to NEV sustainability, as aluminum is highly recyclable, with recycled alloys retaining most of their mechanical properties. This aligns with the environmental goals of the automotive industry, reducing the carbon footprint of vehicle production. As NEVs continue to evolve, the demand for innovative aluminum casting designs—optimized for strength, weight, and thermal management—will grow, solidifying their role as critical components in the transition to sustainable mobility.

Read recommendations:

extruded aluminum electronics enclosure