2025-08-19 hits:0 source:corten steel fabricators

LED lighting systems—from industrial high-bay lights and commercial downlights to residential bulbs and automotive headlights—rely heavily on effective heat dissipation to maintain performance, longevity, and light quality. Unlike traditional incandescent or fluorescent bulbs, LEDs generate significant heat at their semiconductor junctions; if this heat is not removed promptly, junction temperatures rise above the safe threshold (typically 85°C-120°C for most LEDs), leading to reduced light output (lumen depreciation), color shifting (e.g., warm white turning cool white), and shortened lifespan (from 50,000+ hours to as little as 10,000 hours). Die-cast heat sinks have emerged as a preferred solution for LED cooling, offering a unique combination of thermal efficiency, design flexibility, and cost-effectiveness.

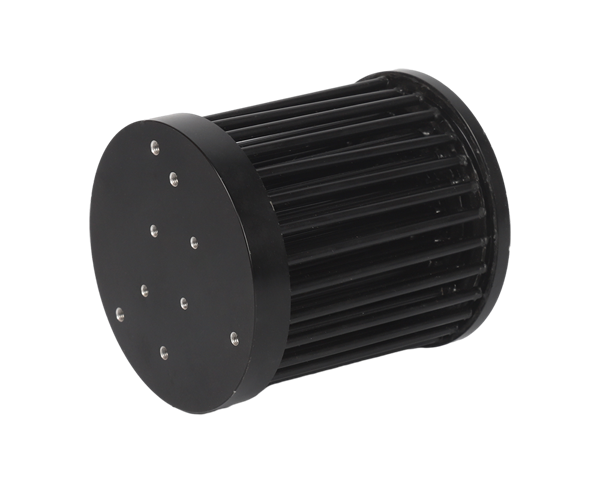

The primary advantage of die-cast heat sinks for LEDs is their excellent thermal conductivity, enabled by the use of high-performance metals like aluminum (e.g., ADC12, A380) or magnesium alloys. Aluminum die-cast heat sinks, the most common type, have a thermal conductivity of 96-151 W/m·K—significantly higher than plastic or extruded aluminum alternatives—allowing them to quickly absorb heat from the LED module and dissipate it into the surrounding environment. Additionally, die-casting technology enables the creation of complex, intricate heat sink structures (e.g., fin arrays with variable heights, thin walls, and internal cavities) that maximize surface area for heat transfer. For example, a die-cast heat sink for a 100W industrial LED high-bay light may feature 50+ thin, closely spaced fins (1-2mm thick) arranged in a radial or grid pattern, increasing surface area by 300-500% compared to simple extruded designs. This complex geometry ensures even heat distribution and efficient convection cooling, keeping LED junction temperatures within safe limits.

Die-cast heat sinks also offer design versatility to match the diverse form factors of LED lighting. For compact residential LED bulbs, die-casting can produce small, lightweight heat sinks (weighing 10-30g) with integrated mounting threads or clips for easy assembly with the bulb’s base. For large-scale commercial lighting (e.g., LED streetlights), die-cast heat sinks can be manufactured as part of the light’s housing, combining structural support with cooling functionality—this integration reduces component count, simplifies assembly, and lowers production costs. Moreover, die-casting allows for the incorporation of thermal interface features (e.g., flat, smooth surfaces for direct contact with the LED module) with tight dimensional tolerances (±0.1mm), ensuring minimal thermal resistance between the LED and heat sink.

Durability and environmental resistance are additional benefits of die-cast heat sinks in LED lighting. Most die-cast heat sinks undergo surface treatments like anodizing (creating a hard, corrosion-resistant oxide layer), powder coating, or electrophoretic deposition (EPD) to protect against moisture, dust, and chemical exposure—critical for outdoor LED applications (e.g., streetlights, floodlights) or harsh industrial environments. Anodized aluminum heat sinks, for instance, have a corrosion resistance rating of ISO 9227 (salt spray test) for 500+ hours, ensuring long-term performance in rainy or coastal areas.

In practical applications, die-cast heat sinks are paired with other cooling components (e.g., thermal pads, fans) for enhanced performance. For high-power LEDs (200W+), a die-cast heat sink with an integrated fan (active cooling) can reduce junction temperatures by 15-25°C compared to passive cooling alone. Additionally, thermal simulation software (e.g., ANSYS Icepak, SolidWorks Flow Simulation) is used during the die-cast heat sink design phase to optimize fin geometry, predict heat dissipation performance, and ensure compliance with LED manufacturer thermal requirements. By combining high thermal efficiency, design flexibility, and durability, die-cast heat sinks play a critical role in unlocking the full potential of LED lighting technology, enabling energy-efficient, long-lasting illumination across residential, commercial, and industrial sectors.

Read recommendations: