2025-06-06 hits:0 source:corten steel fabricators

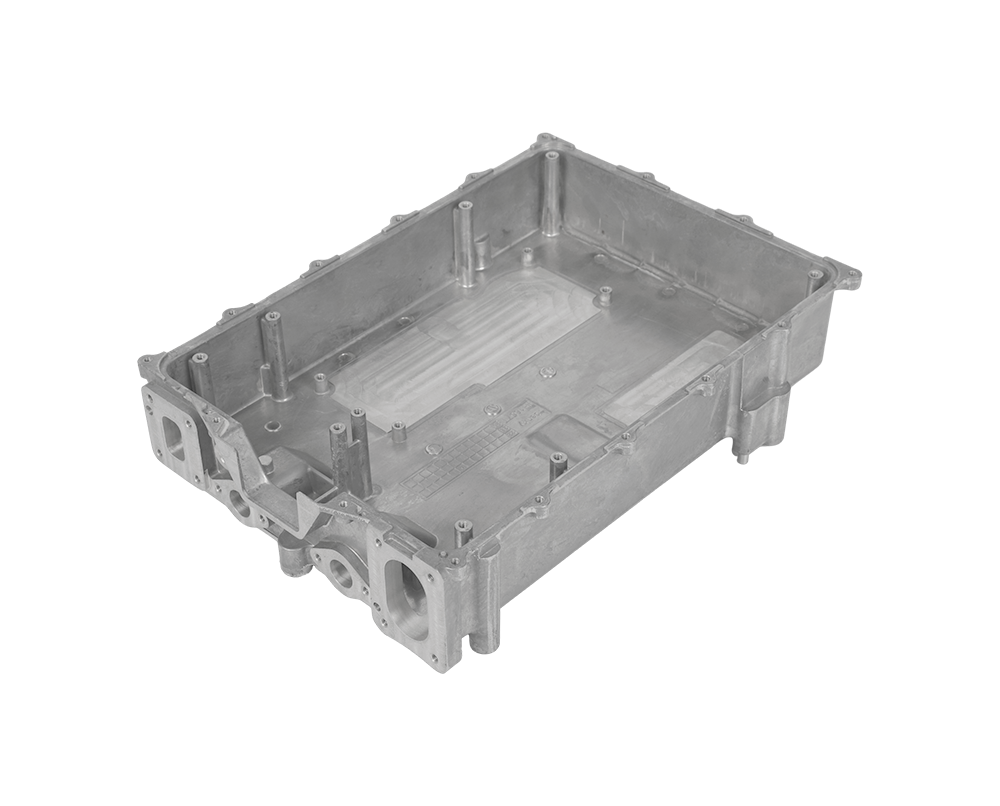

The concealment design of aluminum die - castings is an important aspect in modern product design, aiming to create products with a clean, seamless appearance while maintaining functionality and structural integrity. This design concept is widely applied in various industries, from consumer electronics to automotive and furniture.

One of the main reasons for the concealment design of aluminum die - castings is to enhance the aesthetic appeal of products. By hiding visible seams, fasteners, and other structural elements, products can achieve a more streamlined and sophisticated look. For example, in consumer electronics, such as laptops and smartphones, aluminum die - castings are often used for the housing. Concealment design techniques can be employed to integrate components like hinges, ports, and buttons in a way that they are almost invisible when not in use. This not only improves the visual appeal but also gives the product a high - end and premium feel.

In the automotive industry, the concealment design of aluminum die - castings is crucial for both aesthetics and aerodynamics. Components such as engine mounts, suspension parts, and body structural elements can be designed with concealed joints and fasteners. This not only reduces air resistance but also gives the vehicle a more elegant and unified appearance. Additionally, concealed designs can protect internal components from external damage and environmental factors, improving the overall durability of the vehicle.

To achieve effective concealment design, several techniques are commonly used. One approach is to use hidden fasteners, such as internal screws or snap - fit mechanisms. These fasteners are located inside the casting or in areas that are not easily visible, ensuring that the outer surface of the product remains smooth and uncluttered. Another technique is to integrate functional elements into the shape of the casting. For example, cooling channels in an aluminum die - cast heat sink can be designed in a way that they are hidden within the structure, without affecting the overall appearance of the component.

Moreover, the surface treatment of aluminum die - castings also contributes to the concealment design. Finishes like smooth polishing, anodizing with a uniform color, or powder coating can help mask any minor imperfections or seams, creating a more seamless look. However, concealment design should not compromise the functionality and manufacturability of the aluminum die - castings. Designers need to carefully balance aesthetic requirements with engineering considerations to ensure that the final product meets both the visual and performance standards.

Read recommendations:

Experience Sharing of Die Casting Companies in Cleaning Die Castings