2025-07-28 hits:0 source:News

Magnesium alloy die-cast enclosures have gained prominence in industries ranging from electronics to automotive due to their unique combination of mechanical, physical, and economic benefits. One of the most significant advantages is their exceptional strength-to-weight ratio. Magnesium, the lightest structural metal, offers a density of approximately 1.7 g/cm³—about 33% lighter than aluminum and 75% lighter than steel. This lightweight property is critical for applications where weight reduction is paramount, such as portable electronic devices (laptops, tablets) and electric vehicles, as it improves energy efficiency and reduces operational costs.

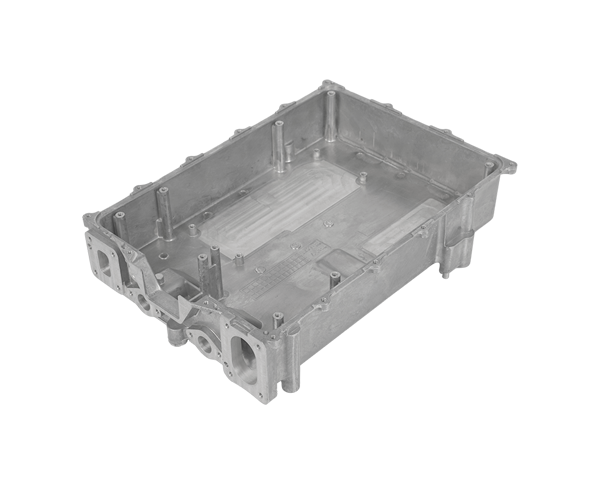

Despite their low weight, magnesium alloy enclosures maintain impressive mechanical performance. They exhibit good tensile strength (200–350 MPa) and impact resistance, ensuring durability in harsh environments. Their high damping capacity—up to five times greater than aluminum—makes them ideal for housing sensitive components like sensors or circuit boards, as they absorb vibrations and reduce noise, enhancing overall device stability.

From a manufacturing perspective, magnesium alloys offer excellent castability. Their low melting point (around 650°C, lower than aluminum’s 660°C) and high fluidity allow for intricate die-casting of complex geometries with tight tolerances (±0.1 mm for small parts). This precision reduces the need for post-processing, streamlining production and lowering costs. Additionally, magnesium die casts have smooth surface finishes, minimizing the need for extensive polishing or machining before assembly.

Thermal management is another key advantage. Magnesium alloys conduct heat efficiently (70–150 W/m·K), dissipating heat generated by internal components—such as processors in electronics—more effectively than plastics or some metals. This thermal conductivity helps prevent overheating, extending the lifespan of enclosed devices.

Environmentally, magnesium is highly recyclable, with a recycling process that consumes only 5% of the energy required for primary production, aligning with sustainable manufacturing goals. While magnesium alloys are more expensive than plastics, their long-term benefits—including durability, recyclability, and performance—often offset the initial cost, making them a compelling choice for high-performance enclosures.

Read recommendations:

80 20 t slot aluminum extrusions

What are the key points of die casting processing.rapid prototyping sheet metal

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible