2025-06-16 hits:0 source:News

The alloy die-casting process for aeroengine blades is a highly sophisticated and precision-oriented manufacturing technique that plays a crucial role in the aerospace industry. Aeroengine blades operate under extreme conditions, including high temperatures, intense mechanical stresses, and corrosive environments, demanding materials and manufacturing processes that can ensure superior performance and reliability.

The first step in the alloy die-casting process for aeroengine blades involves the selection of appropriate alloy materials. Typically, nickel-based superalloys are favored due to their exceptional high-temperature strength, oxidation resistance, and creep resistance. These alloys contain a complex combination of elements such as nickel, chromium, cobalt, and titanium, which work together to enhance the material's mechanical properties. Once the alloy is selected, it is melted in a high-temperature furnace under carefully controlled conditions to ensure a homogeneous melt with consistent chemical composition.

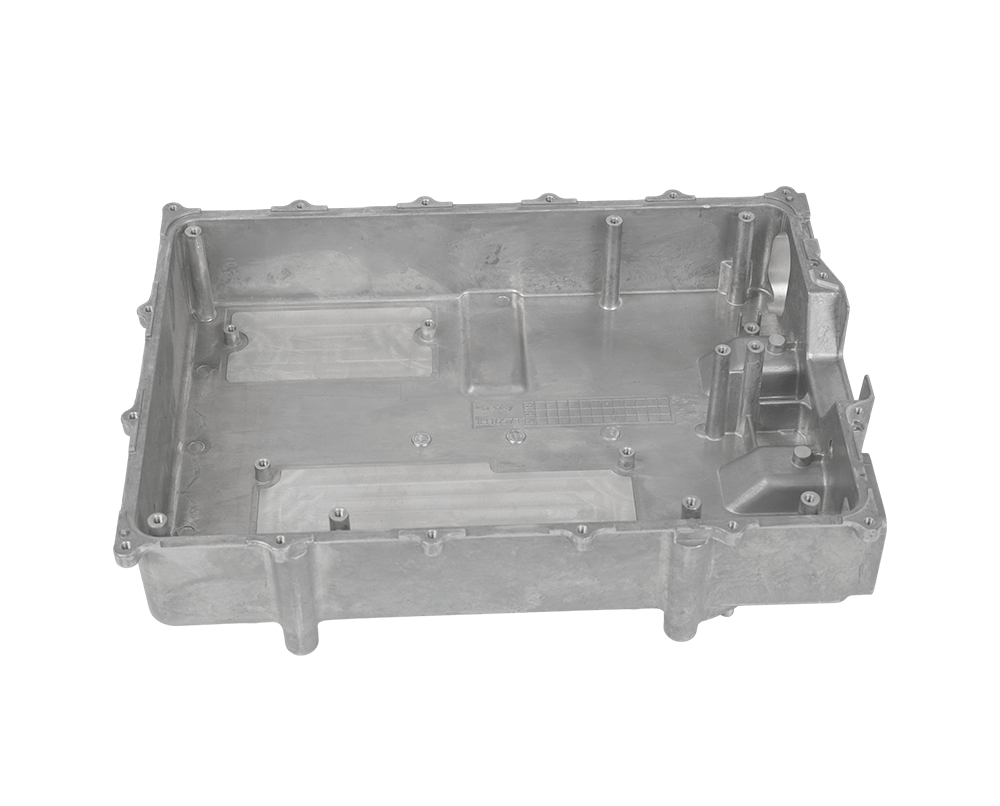

The die-casting process itself utilizes a specialized mold, often referred to as a die. The die is designed to precisely replicate the intricate shape of the aeroengine blade, including its airfoil profile, cooling channels, and attachment features. High-pressure injection systems are employed to force the molten alloy into the die cavity at extremely high speeds. This rapid injection helps to fill the complex geometry of the blade accurately and minimizes the formation of air bubbles or voids within the casting. The high pressure also ensures good surface finish and dimensional accuracy of the blade.

After the molten alloy is injected into the die, it is allowed to cool and solidify. Cooling is a critical stage as it affects the microstructure and mechanical properties of the blade. To achieve the desired microstructure, advanced cooling techniques such as rapid solidification and controlled cooling rates are implemented. These techniques can refine the grain size of the alloy, improve its strength and toughness, and enhance its resistance to fatigue and creep. Once the blade is fully solidified, the die is opened, and the cast blade is ejected.

Post-casting processes are then carried out to further enhance the quality of the aeroengine blade. These may include heat treatment operations such as solution annealing, aging, and hot isostatic pressing (HIP). Heat treatment helps to relieve internal stresses, improve the alloy's mechanical properties, and optimize its microstructure. Machining operations are also performed to achieve the final dimensions and surface finish required for the blade. This may involve processes such as milling, grinding, and electro-discharge machining (EDM) to precisely shape the blade and create features like cooling holes and attachment interfaces. Quality control measures, including non-destructive testing methods such as X-ray inspection, ultrasonic testing, and dye penetrant inspection, are rigorously applied throughout the manufacturing process to ensure that the aeroengine blades meet the stringent requirements of the aerospace industry.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible