2025-07-11 hits:0 source:News

Alloy die casting plays a vital role in the production of ophthalmic medical equipment, where precision, biocompatibility, and durability are paramount. Ophthalmic devices such as slit lamps, tonometers, and ophthalmoscopes require components with intricate geometries and tight tolerances, often within ±0.02 mm, to ensure accurate diagnostics and patient safety.

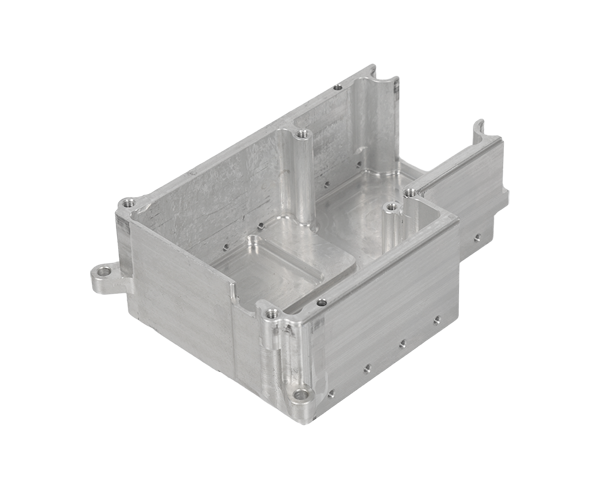

Aluminum alloys, particularly Al-Si-Mg series (e.g., A380), are widely used due to their excellent castability, lightweight properties, and good corrosion resistance. These alloys can be die-cast into complex shapes, such as the housing of retinal cameras or the adjustment knobs of phoropters, with smooth surface finishes (Ra 1.6–3.2 μm) that minimize bacterial adhesion—critical for medical environments. Magnesium alloys are also employed in portable ophthalmic tools (e.g., hand-held refractometers) to reduce weight without compromising structural strength.

The die casting process for ophthalmic equipment demands strict quality control. Porosity must be minimized to prevent fluid ingress and ensure sterility, often achieved through high-pressure die casting (HPDC) with pressures ranging from 400 to 1200 bar. Post-casting treatments like anodizing or passivation enhance corrosion resistance, while precision machining ensures components fit seamlessly, avoiding misalignment that could affect diagnostic accuracy. Compliance with medical standards such as ISO 13485 is mandatory, requiring traceability of raw materials and rigorous testing (e.g., ultrasonic inspection) to detect defects.

Read recommendations:

rectangular aluminum extrusion profiles

automotive metal stamping companies

black anodized aluminum t slot

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible