2025-05-16 hits:0 source:News

Aluminum die - castings have emerged as a pivotal material in the manufacturing of smart kitchen equipment, revolutionizing the industry with their unique properties and versatile applications. Smart kitchen equipment, which encompasses a wide range of devices such as smart ovens, induction cooktops, coffee makers, and food processors, demands components that are not only functional but also lightweight, durable, and aesthetically pleasing. Aluminum die - castings perfectly meet these requirements, making them an ideal choice for modern kitchen appliance manufacturers.

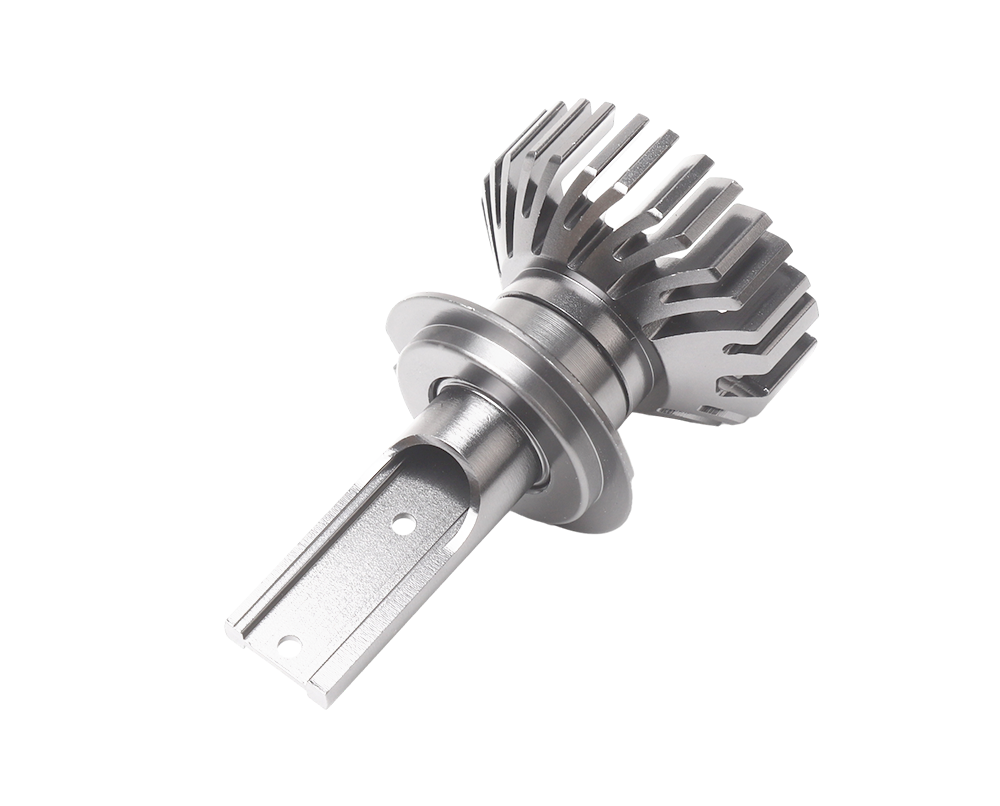

The die - casting process involves injecting molten aluminum under high pressure into a mold cavity, which allows for the production of complex shapes with high precision and repeatability. This process enables the creation of intricate designs and features that are essential for the functionality of smart kitchen equipment. For example, in smart ovens, aluminum die - castings can be used to fabricate the internal components such as the heating element supports, fan housings, and control panel frames. These components need to be precisely shaped to ensure proper heat distribution, efficient air circulation, and seamless integration of electronic controls.

One of the key advantages of aluminum die - castings in smart kitchen equipment is their excellent thermal conductivity. Aluminum is a highly efficient conductor of heat, which means that components made from it can quickly transfer heat, enabling faster cooking times and more even heat distribution in appliances like cooktops and ovens. This property also helps in dissipating heat generated by electronic components, preventing overheating and ensuring the long - term reliability of the smart kitchen devices.

In addition to thermal conductivity, aluminum die - castings offer good electrical insulation properties, which is crucial for the safety and functionality of smart kitchen equipment. With the increasing integration of electronics in modern kitchen appliances, having components that can insulate electrical circuits effectively is essential to prevent short - circuits and electrical hazards. Moreover, aluminum is a non - ferrous metal, which means it is resistant to magnetic interference, making it suitable for use in devices with sensitive electronic components.

Another significant benefit of using aluminum die - castings in smart kitchen equipment is their lightweight nature. Compared to other metals like steel, aluminum is much lighter, which reduces the overall weight of the kitchen appliances. This not only makes the equipment easier to handle and install but also contributes to energy savings during transportation. Additionally, the lightweight characteristic of aluminum die - castings allows for more innovative and ergonomic designs, enhancing the user experience in the kitchen.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible