2025-07-18 hits:0 source:News

Pure aluminum die-casting has emerged as a critical manufacturing technology for instruments and meters, driven by the demand for lightweight, corrosion-resistant, and dimensionally precise components. In this field, the purity of aluminum (typically ≥99%) is leveraged to achieve specific properties, such as high electrical conductivity for sensors and low magnetic permeability for electromagnetic-sensitive devices.

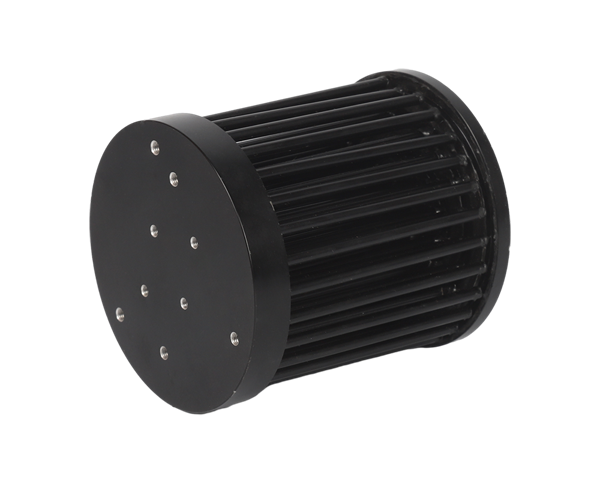

One of the primary applications of pure aluminum die-casting in instruments is the production of housing components for analytical equipment, such as spectrometers and chromatographs. These housings must protect internal electronics from environmental factors like moisture, dust, and mechanical shock while maintaining thermal stability. Pure aluminum’s excellent thermal conductivity (approximately 205 W/m·K) allows for efficient heat dissipation, preventing overheating in sensitive electronic modules. For example, in high-precision temperature control systems, pure aluminum heat sinks integrated into the housing ensure uniform heat distribution, maintaining the accuracy of temperature sensors.

In metrology tools, such as coordinate measuring machines (CMMs), pure aluminum die-casting is used to fabricate structural components that require minimal thermal expansion. Aluminum’s low coefficient of thermal expansion (23.1×10⁻⁶/°C) compared to other metals like iron (11×10⁻⁶/°C) ensures that dimensional stability is preserved across varying temperature ranges, critical for maintaining measurement accuracy. Additionally, pure aluminum’s non-magnetic properties make it ideal for components in magnetic resonance imaging (MRI) accessories or electrical meters, where interference from external magnetic fields must be minimized.

The die-casting process for pure aluminum in instruments often involves high-pressure techniques to achieve intricate geometries, such as thin-walled enclosures with internal ribs for structural reinforcement. Surface finishing processes like anodizing are commonly applied to enhance corrosion resistance and provide a non-conductive coating for electrical insulation. For instance, anodized pure aluminum housings for pH meters offer chemical resistance against aggressive solutions while maintaining electrical isolation between internal circuits and external environments.

However, pure aluminum’s lower strength compared to aluminum alloys (tensile strength ~90 MPa vs. 200–300 MPa for alloys) limits its use in load-bearing components. To address this, designers often incorporate hybrid structures, combining pure aluminum for specific functional surfaces with alloy reinforcements in stress-bearing areas. Despite these challenges, pure aluminum die-casting remains indispensable in instruments and meters, where its unique physical properties directly enable the performance and reliability of precision equipment.

Read recommendations:

2020 v slot aluminum profile extrusion

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible