2025-06-19 hits:0 source:News

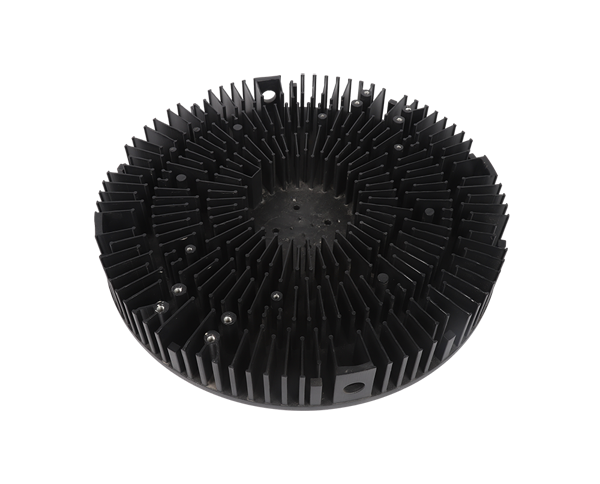

Aluminum die casting with metal molds is a widely - used manufacturing process that offers high - volume production capabilities with excellent dimensional accuracy and surface finish. This process involves injecting molten aluminum under high pressure into a reusable metal mold, also known as a die.

The metal mold used in aluminum die casting is typically made from high - strength tool steels. These molds are designed with two or more parts that can be opened and closed to allow for the insertion of the molten metal and the removal of the finished casting. The mold cavities are precisely machined to the desired shape of the part, including all the intricate details, holes, and bosses. Before the molten aluminum is injected, the mold is pre - heated and coated with a release agent to prevent the aluminum from sticking to the mold surfaces and to facilitate easy ejection of the casting after solidification.

One of the key advantages of aluminum die casting with metal molds is the high production rate. Once the mold is set up, parts can be produced in rapid succession, making it suitable for mass - production applications. The process also enables the creation of complex geometries with thin walls, which is difficult to achieve with other casting methods. Additionally, the high - pressure injection ensures good filling of the mold cavities, resulting in castings with dense microstructures and excellent mechanical properties. Aluminum castings produced through this process have good corrosion resistance, high strength - to - weight ratio, and good thermal conductivity, making them ideal for applications in the automotive, aerospace, electronics, and consumer goods industries. For example, in the automotive industry, aluminum die - cast parts are commonly used for engine components, transmission housings, and wheel rims. However, this process also has some limitations. The initial cost of creating the metal mold is relatively high, which makes it more cost - effective only for large - volume production runs. Moreover, the high - pressure injection may introduce air bubbles or porosity in the castings, which may require additional post - processing steps such as heat treatment or machining to improve the quality.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible