2025-04-28 hits:0 source:News

Aluminum profile extrusion machine equipment is the cornerstone of the aluminum profile manufacturing industry, playing a pivotal role in transforming aluminum ingots or billets into a wide variety of customized profiles. This sophisticated machinery operates on a well - defined principle that combines high pressure, precise temperature control, and specialized dies to shape aluminum into the desired forms.

The extrusion process begins with the heating of aluminum billets. The billets are typically pre - heated to a specific temperature range, usually between 400°C and 550°C, depending on the alloy composition. This heating softens the aluminum, making it malleable enough to be forced through the extrusion die. The heated billet is then placed into the container of the extrusion press. The extrusion press, which is the core component of the equipment, exerts immense pressure on the billet. Hydraulic systems are commonly used in modern extrusion machines to generate this pressure, which can range from several hundred to several thousand tons.

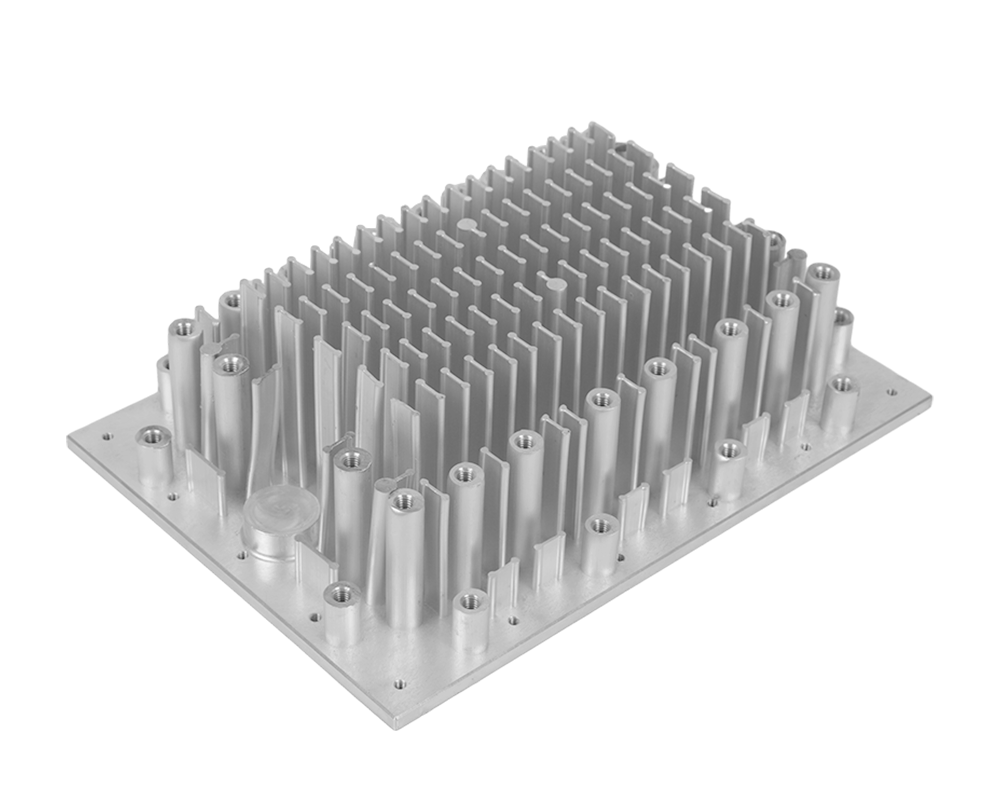

As the pressure is applied, the softened aluminum is pushed through the extrusion die. The die is a critical component that determines the cross - sectional shape of the final aluminum profile. Dies can be designed to produce a vast array of shapes, including simple shapes like channels, angles, and tubes, as well as complex, custom - designed profiles for specific applications. The precision of the die design is crucial, as even the slightest deviation can result in defective profiles.

To ensure the quality of the extruded profiles, the extrusion machine is equipped with various control systems. Temperature control systems monitor and regulate the temperature of the billet, the die, and the extrusion process itself. Maintaining the correct temperature is essential to prevent issues such as surface defects, uneven extrusion, or material cracking. Additionally, speed control systems manage the rate at which the aluminum is extruded. The extrusion speed affects the quality and consistency of the profile, and it needs to be adjusted according to the alloy type, die design, and other factors.

Modern aluminum profile extrusion machine equipment also incorporates advanced automation features. Computer - controlled systems can precisely manage the entire extrusion process, from billet loading to profile cutting. These systems can store and recall extrusion parameters for different alloys and profile designs, ensuring repeatability and reducing the likelihood of human error. Furthermore, sensors are used to monitor various aspects of the extrusion process, such as pressure, temperature, and profile dimensions, in real - time. Any deviations from the set parameters can trigger automatic adjustments or alarms, allowing operators to take corrective actions promptly.

In addition to the extrusion press and related control systems, aluminum profile extrusion machine equipment may also include auxiliary components. These can include billet heating furnaces, which ensure uniform heating of the billets; cooling systems, which rapidly cool the extruded profiles to set their shape and properties; and cutting devices, which trim the profiles to the desired length. The combination of all these components enables the production of high - quality aluminum profiles in large quantities, meeting the diverse demands of industries such as construction, automotive, aerospace, and electronics.

Read recommendations:

aluminum radius corner extrusion

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible