2025-07-25 hits:0 source:News

Analysis of Water Defects in Zinc Alloy Die Casting Products

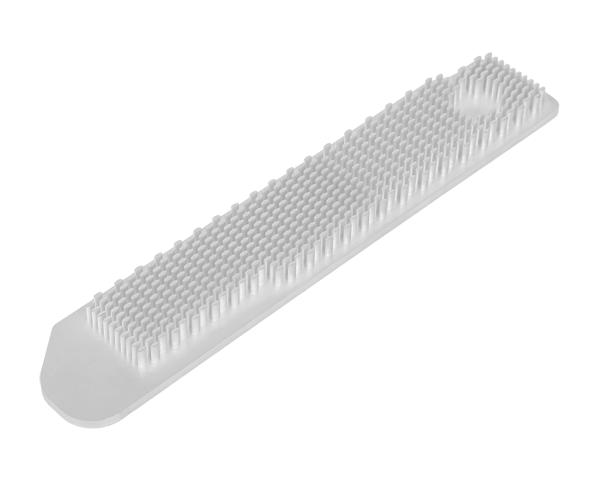

Water defects, also known as flow lines or striations, are visible irregularities on the surface of zinc alloy die castings, appearing as wavy or banded patterns. These defects arise from improper filling of the mold cavity and can compromise both aesthetics and structural integrity, requiring targeted solutions to eliminate them.

The primary cause is uneven flow of the molten zinc alloy during injection. When the alloy enters the mold at varying speeds or temperatures, cooler, slower-moving layers mix with hotter, faster layers, creating visible boundaries. This often occurs due to excessive injection speed differences between sections of the mold or abrupt changes in cavity geometry (e.g., thick-to-thin wall transitions).

Inadequate mold temperature exacerbates the issue. Cold mold surfaces cause the molten alloy to solidify prematurely, forming a skin that is then disturbed by subsequent flow. Molds should be preheated to 150°C to 200°C, with uniform temperature distribution via coolant channels to prevent localized cooling.

Poor gating design is another contributor. Gases trapped in the mold due to insufficient venting can disrupt flow, creating turbulence that leads to water . Optimizing gate size and location—placing gates to align with the main flow direction—and adding vents in low-pressure areas (e.g., cavity extremities) allows smooth, uninterrupted filling.

Adjusting process parameters helps mitigate water . Increasing the molten alloy temperature (within the 380°C–420°C range) improves fluidity, while reducing injection speed variations ensures consistent flow. Using a slower initial injection phase to fill the gate area, then increasing speed for the main cavity, minimizes turbulence.

Post-casting, polishing can sometimes mask minor water ,but eliminating the root cause—optimizing flow dynamics, mold temperature, and gating—is critical for high-quality, defect-free zinc alloy castings used in decorative or structural applications.

Read recommendations:

20x20 extruded aluminium profile

extruded aluminum trim profiles

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible