2025-06-24 hits:0 source:News

In the advanced field of robot manufacturing, where precision, durability, and lightweight design are essential, pure aluminum die-casting plays a vital role in creating high-performance robotic components.

One of the main applications of pure aluminum die-casting in robot manufacturing is in the production of robotic arms. Robotic arms need to be strong enough to carry heavy payloads while being lightweight to enable fast and precise movements. Pure aluminum die-cast robotic arms offer an excellent strength-to-weight ratio. The die-casting process allows for the creation of complex internal structures within the arm, such as hollow chambers for routing cables and pipes, reducing the weight without sacrificing strength. For example, in industrial robotic arms used in automotive manufacturing, die-cast aluminum arms can move heavy car parts with high precision, improving the efficiency and accuracy of the assembly process.

Another significant application is in the manufacturing of robot joints. Joints are critical components that enable the movement of robotic limbs. They need to be durable, have low friction, and be able to withstand repeated mechanical stress. Pure aluminum die-cast joint components, such as brackets and bearing housings, provide the necessary strength and wear resistance. The smooth surface finish of die-cast parts reduces friction, allowing for smooth and efficient movement of the joints. Additionally, the corrosion resistance of pure aluminum ensures that the joint components remain in good condition even in harsh industrial environments, where exposure to moisture, chemicals, and dust is common.

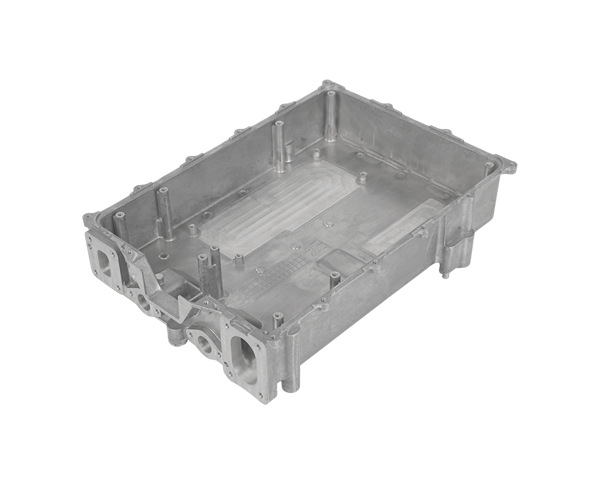

Pure aluminum die-casting is also used for manufacturing robot chassis and frames. The chassis serves as the foundation of the robot, supporting all the other components. Die-cast aluminum chassis offer a combination of strength, rigidity, and lightweight design. They can be designed with integrated mounting points for motors, sensors, and other subsystems, simplifying the assembly process. The ability to create complex geometries through die-casting allows for the optimization of the chassis structure, enhancing the robot's stability and performance. In service robots, such as delivery robots used in hospitals or hotels, the lightweight die-cast aluminum chassis enables the robot to move quietly and efficiently, reducing energy consumption.

Furthermore, pure aluminum die-casting can be applied to the production of robot enclosures and covers. These enclosures protect the internal electronic components of the robot from external factors, such as dust, moisture, and electromagnetic interference. Die-cast aluminum enclosures provide excellent shielding properties and can be designed with ventilation holes and heat dissipation features to ensure the proper functioning of the electronics. The aesthetic appeal of die-cast aluminum enclosures also allows for the creation of visually appealing robot designs, which is important in consumer-oriented robots, such as home service robots.

Read recommendations:

Starting from here, improving the value of zinc alloy die castings

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible