2025-08-04 hits:0 source:News

Electroplating aluminum die castings offers a multitude of benefits that enhance their performance, durability, and aesthetic appeal, making the process indispensable in industries ranging from automotive to consumer electronics. Aluminum die castings are valued for their lightweight properties, complex geometric capabilities, and cost-effectiveness, but their inherent vulnerabilities—such as low corrosion resistance and poor wear resistance—are effectively addressed through electroplating.

One of the primary advantages is enhanced corrosion resistance. Aluminum naturally forms a thin oxide layer, but this layer is porous and insufficient to protect against harsh environments, especially those containing moisture, salt, or industrial chemicals. Electroplating deposits a dense, impermeable metal layer—such as nickel, chrome, or zinc—over the aluminum surface, acting as a physical barrier that prevents corrosive agents from reaching the base metal. For example, zinc-nickel plating provides superior protection in automotive applications, where die cast components like engine brackets or door handles are exposed to road salts and humidity, extending their service life by 5–10 times compared to unplated parts.

Electroplating also significantly improves wear and abrasion resistance. Aluminum has a relatively low hardness (typically 60–100 HV), making it prone to scratching, galling, or deformation in high-friction applications. Plating with hard metals such as chromium (hardness up to 1000 HV) or nickel-phosphorus alloys creates a surface that can withstand repeated mechanical contact. This is critical for components like hydraulic valve bodies or gearbox housings, where friction between moving parts would otherwise cause rapid degradation. The hard plated layer reduces surface wear, minimizing maintenance needs and ensuring consistent performance over time.

Aesthetic enhancement is another key benefit. Aluminum die castings often have uneven surfaces due to the casting process, with visible pores or imperfections. Electroplating creates a smooth, uniform finish that can be tailored to meet specific visual requirements—from bright chrome-like mirrors to matte or textured surfaces. This is particularly valuable in consumer goods, such as smartphone housings, furniture hardware, or decorative fixtures, where appearance directly influences product appeal. Plating also allows for color customization through techniques like black nickel plating or gold plating, enabling brand-specific design language.

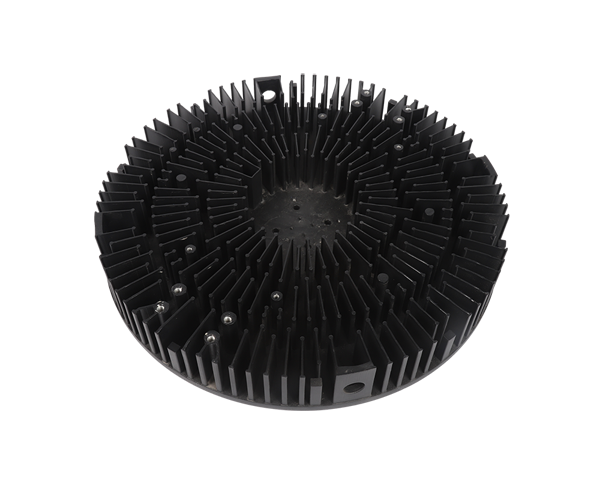

Additionally, electroplating can improve electrical conductivity or thermal performance of aluminum die castings. For electrical components like heat sinks or connectors, plating with copper (an excellent conductor) enhances current flow or heat dissipation, complementing aluminum’s natural thermal conductivity. In aerospace applications, where weight and conductivity are critical, copper-plated aluminum die castings offer a lightweight alternative to solid copper parts, reducing overall system weight without sacrificing performance.

Finally, electroplating provides a cost-effective solution compared to using more expensive materials. Instead of manufacturing components from corrosion-resistant but costly metals like stainless steel, aluminum die castings can be plated to achieve similar properties at a fraction of the cost. This balance of performance and affordability makes electroplated aluminum die castings a preferred choice in mass production, driving their widespread adoption across diverse industries.

Read recommendations:

aluminium construction profiles

extruded aluminium enclosure.Customized aluminum alloy die-casting

This is something that aluminum alloy die-casting factories need to do before opening the mold

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible