2025-05-14 hits:0 source:News

Chemical polishing of aluminum profiles is a crucial surface - treatment process that significantly enhances the aesthetic and functional properties of aluminum products. This process involves immersing aluminum profiles in a chemical solution, typically composed of strong acids such as phosphoric acid, sulfuric acid, and nitric acid, along with various additives. The chemical reaction between the aluminum surface and the solution selectively dissolves the microscopic peaks and valleys on the surface, resulting in a smooth, mirror - like finish.

The mechanism of chemical polishing is based on the differential dissolution rate of aluminum at different surface areas. The protruding parts of the aluminum surface, which have a higher local current density, dissolve more rapidly than the recessed areas. As the reaction progresses, the surface gradually becomes smoother, reducing the surface roughness. The addition of additives in the chemical solution plays a vital role in controlling the reaction rate and improving the quality of the polished surface. For example, certain additives can form a thin, protective film on the aluminum surface, preventing excessive dissolution and ensuring a uniform polishing effect.

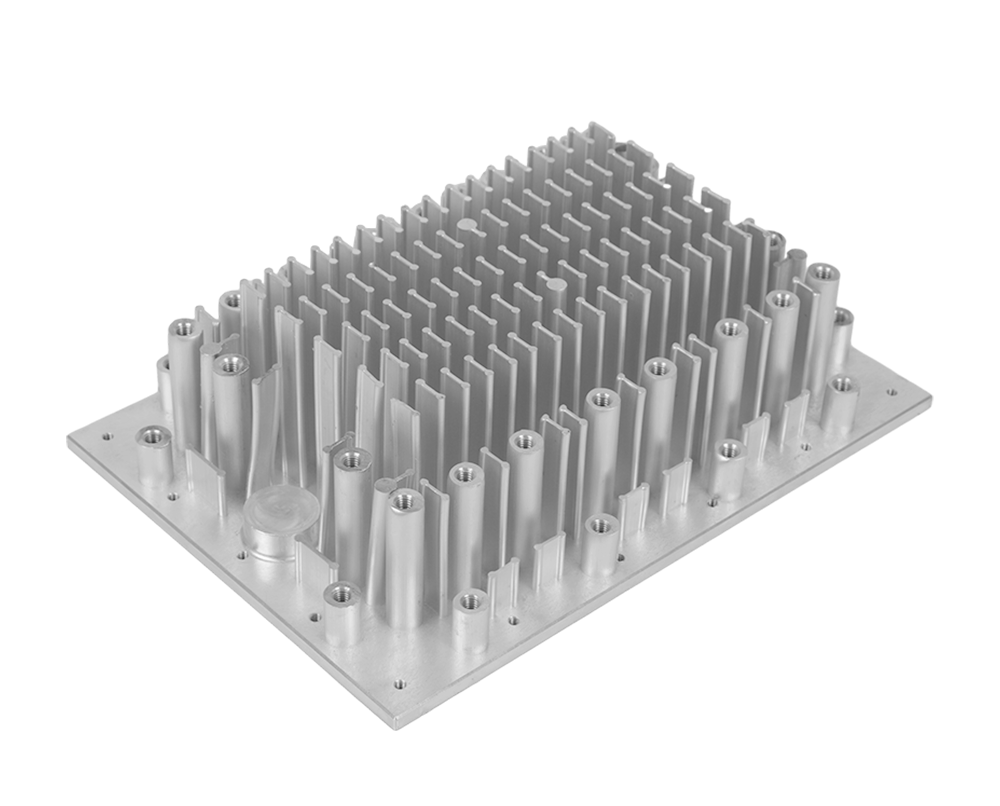

One of the significant advantages of chemical polishing for aluminum profiles is its ability to achieve a high - quality surface finish without the need for mechanical abrasion. This is particularly beneficial for complex - shaped aluminum profiles, where traditional mechanical polishing methods may be difficult to apply. Chemical polishing can also improve the corrosion resistance of aluminum profiles. The smooth surface reduces the likelihood of moisture and corrosive substances adhering to the surface, thereby protecting the aluminum from oxidation and corrosion.

In the manufacturing of architectural aluminum profiles, chemical polishing is widely used to enhance the visual appeal of the products. Polished aluminum profiles are often used in building facades, window frames, and interior decorations, as they can provide a sleek, modern appearance. In the automotive industry, chemical - polished aluminum components not only improve the aesthetic value of the vehicle but also contribute to weight reduction, as the process does not significantly increase the thickness of the material.

However, chemical polishing also presents some challenges. The chemical solutions used are highly corrosive, requiring strict safety measures during handling and proper waste - treatment procedures to prevent environmental pollution. Additionally, controlling the chemical - polishing process precisely to achieve consistent results across different batches of aluminum profiles can be complex, as factors such as temperature, concentration of the chemical solution, and immersion time need to be carefully monitored and adjusted.

Read recommendations:

80 20 t slot aluminum extrusions

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible