2025-06-07 hits:0 source:News

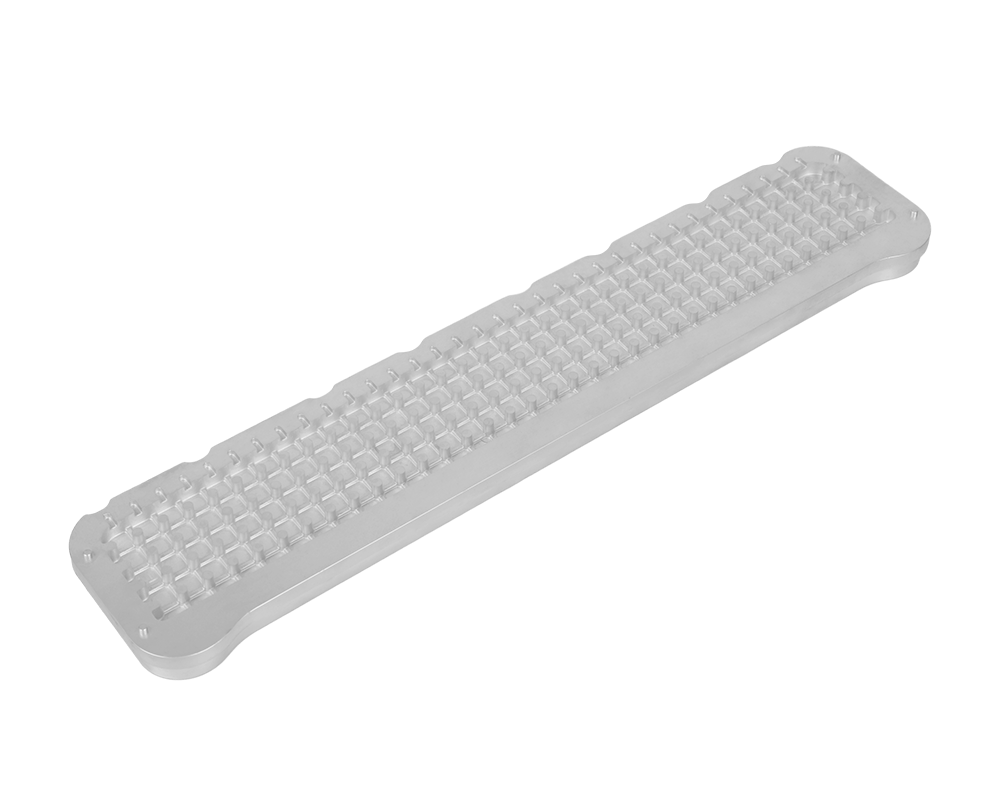

The cleaning efficiency of aluminum die - castings is a crucial factor that significantly impacts the subsequent processing, quality, and performance of the final products. Aluminum die - castings often contain various contaminants after the casting process, including release agents, metal oxides, and residual machining chips. To enhance cleaning efficiency, multiple cleaning methods and techniques are employed, each with its own advantages and suitable applications.

One common approach is mechanical cleaning. This method involves using tools such as brushes, abrasives, or high - pressure water jets to physically remove the contaminants from the surface of the aluminum die - castings. High - pressure water jet cleaning, for example, can effectively dislodge stubborn residues and oxides. The high - velocity water stream impacts the surface of the casting, breaking up and flushing away the contaminants. However, the pressure and nozzle design need to be carefully adjusted to avoid damaging the delicate surfaces of the die - castings. Abrasive blasting, another mechanical method, uses fine particles propelled at high speeds to clean the surface. It can remove tough deposits but may also cause surface roughness changes, which requires proper control of the abrasive type, size, and blasting pressure.

Chemical cleaning is also widely used for aluminum die - castings. Alkaline or acidic cleaning solutions are utilized to dissolve and remove contaminants through chemical reactions. Alkaline cleaners are effective in removing release agents and organic residues, while acidic cleaners can dissolve metal oxides. However, chemical cleaning requires strict control of the solution concentration, temperature, and immersion time. Over - exposure to the cleaning solution may cause excessive corrosion of the aluminum surface, while insufficient exposure may lead to incomplete cleaning. Additionally, proper rinsing and drying processes are essential after chemical cleaning to prevent the formation of residues or water spots.

Automated cleaning systems are increasingly adopted to improve cleaning efficiency. These systems integrate multiple cleaning processes, such as pre - soaking, ultrasonic cleaning, and high - pressure rinsing, in a sequential and automated manner. Ultrasonic cleaning, for instance, uses high - frequency sound waves to create microscopic bubbles in the cleaning solution. When these bubbles collapse, they generate intense shockwaves that can penetrate into tiny crevices and pores of the aluminum die - castings, effectively removing contaminants that are difficult to reach by other methods. By optimizing the combination of different cleaning methods and leveraging automated systems, the cleaning efficiency of aluminum die - castings can be maximized, ensuring high - quality surfaces for subsequent coating, assembly, and other processes.

Read recommendations:

Industrial Aluminum Profile Extrusion company

Customers visit Greenway to explore a new chapter of future development

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible