2025-07-29 hits:0 source:News

Die-cast fire-fighting accessory housings play a critical role in ensuring the reliability and durability of fire protection equipment. These housings, typically made from aluminum or zinc alloys, are designed to enclose and protect essential components such as valves, sensors, and control mechanisms in fire extinguishers, sprinkler systems, and fire alarms.

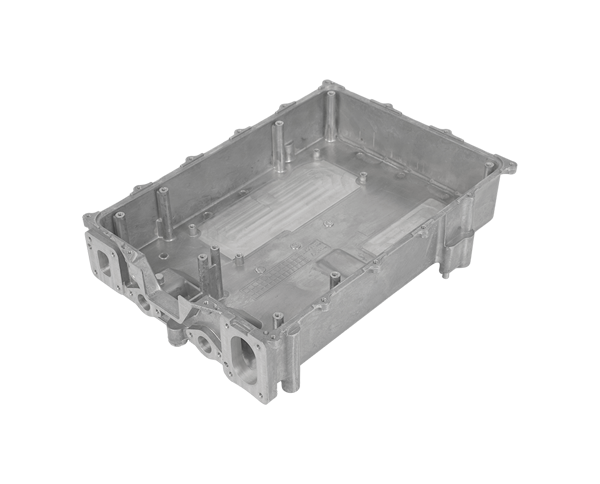

The die-casting process offers several advantages for manufacturing these housings. Aluminum alloys, such as ADC12, are widely preferred due to their excellent combination of strength, corrosion resistance, and lightweight properties. This is crucial for fire-fighting equipment, which often needs to be portable or mounted in various environments, including humid or outdoor settings. The high-pressure die-casting method ensures precise dimensional accuracy, allowing for tight tolerances that ensure proper fitting with other components. This precision reduces the risk of leaks or malfunctions, which could be catastrophic in emergency situations.

Surface treatment is another important aspect. Many fire-fighting accessory housings undergo processes like powder coating or anodizing to enhance their corrosion resistance and withstand harsh conditions, such as exposure to water, chemicals, or extreme temperatures. Additionally, the die-casting process enables the integration of complex features, such as threaded ports, mounting brackets, and internal cavities, in a single production step. This eliminates the need for secondary machining operations, reducing production time and costs while improving overall structural integrity.

Quality control is paramount. Each housing must undergo rigorous testing, including pressure testing to ensure it can withstand the high pressures involved in fire suppression systems, and visual inspections to detect any defects like porosity or cracks. Compliance with industry standards, such as those set by NFPA (National Fire Protection Association), ensures that these housings meet the strict safety requirements necessary for life-saving equipment.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible