2025-08-05 hits:0 source:News

Die-casting aluminum automotive wheel hubs is a specialized manufacturing process that produces lightweight, durable wheel components critical for vehicle performance, safety, and fuel efficiency. Wheel hubs connect the wheel to the vehicle’s axle, transmitting torque and supporting the vehicle’s weight, requiring a combination of high strength, impact resistance, and precise dimensional accuracy—qualities that make die-cast aluminum an ideal choice.

Aluminum alloys used for wheel hubs, such as A356 and 6061, offer a superior strength-to-weight ratio compared to steel, reducing unsprung weight by up to 30%. This reduction improves handling, braking performance, and fuel economy (or battery range in EVs). The alloys are heat-treatable (typically T6 tempering), achieving tensile strengths of 250-350 MPa and excellent fatigue resistance, essential for withstanding the cyclic stresses of road use.

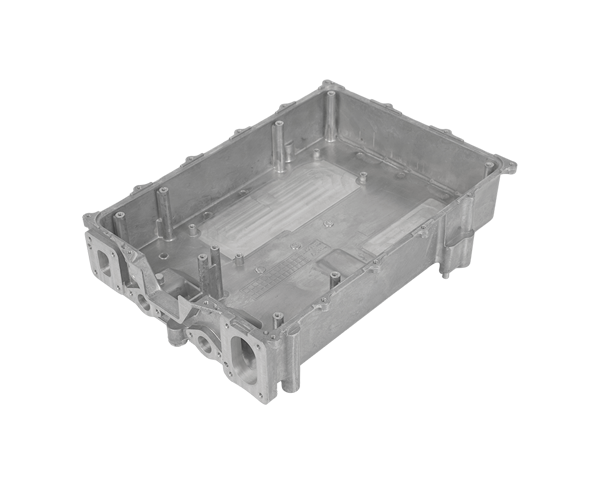

The die-casting process for wheel hubs involves high-pressure injection of molten aluminum (650-700°C) into a steel mold designed to form the hub’s central bore, bolt patterns, and flange. The mold incorporates intricate details, such as splines or keyways for axle connection, and may include reinforcing ribs to enhance structural integrity without adding excessive weight. Vacuum-assisted die casting is often used to eliminate porosity, ensuring the hub can withstand high loads and resist corrosion.

Critical technical considerations include controlling the cooling rate during solidification to produce a fine-grained microstructure, which enhances strength and toughness. The mold is designed with variable cooling channels to ensure uniform solidification across thick and thin sections, preventing defects like shrinkage cavities. After casting, the hub undergoes heat treatment to optimize mechanical properties, followed by precision machining of the bore, flange, and bolt holes to meet tight tolerances (±0.01 mm for bearing fits), ensuring proper alignment and rotation.

Surface treatments for die-cast aluminum wheel hubs include anodizing, powder coating, or electroplating to improve corrosion resistance and aesthetic appeal. Additionally, non-destructive testing (such as X-ray inspection or ultrasonic testing) is performed to detect internal defects that could compromise safety. The use of die-casting for wheel hubs offers advantages like high production efficiency, complex shape capability, and material savings, making it a standard practice in the automotive industry for both passenger cars and commercial vehicles.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible