2025-08-06 hits:0 source:News

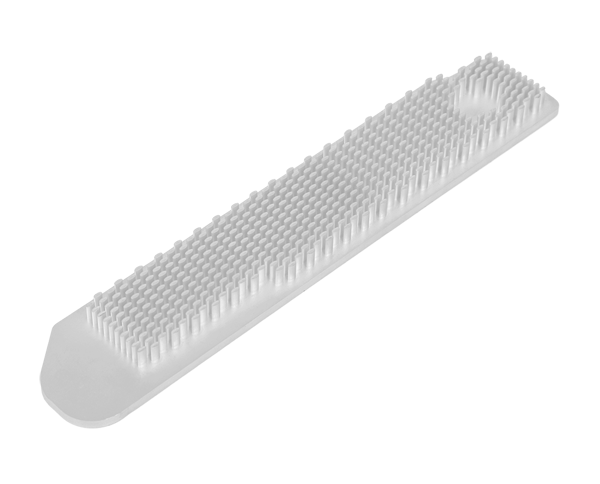

Die-casting radiator processing is a specialized manufacturing technique that produces high-performance heat-dissipating components for automotive, industrial, and electronic applications. Radiators require complex geometries with thin walls, intricate fin structures, and precise dimensional accuracy to maximize heat transfer efficiency, making die-casting an ideal process due to its ability to replicate detailed designs with consistency.

The process begins with the design of a steel mold, which is engineered to create the radiator’s core, fins, and inlet/outlet ports. Aluminum alloys (such as ADC12 or A380) are commonly used for radiators due to their excellent thermal conductivity, lightweight properties, and castability. The molten aluminum, heated to approximately 650-700°C, is injected into the mold under high pressure (typically 10-150 MPa), ensuring that the metal fills even the smallest fin gaps—often as narrow as 1-2 mm—to optimize surface area for heat exchange.

Key technical considerations in die-casting radiator processing include controlling the injection speed and pressure to prevent porosity, which can reduce thermal conductivity and structural integrity. Porosity is minimized by using vacuum-assisted die casting, which removes air from the mold cavity before injection, ensuring dense, uniform metal filling. Additionally, the mold temperature is carefully regulated (between 150-250°C) to control solidification rates, preventing warping in thin-walled sections and ensuring consistent fin spacing.

Post-processing steps are critical to enhance performance. After demolding, radiators undergo trimming to remove excess material (flash) and machining to refine critical surfaces, such as flange connections for hoses. Surface treatments like anodizing or powder coating may be applied to improve corrosion resistance, especially for radiators used in automotive or marine environments. Pressure testing is also performed to detect leaks, ensuring the radiator can withstand the operating pressures of cooling systems.

The advantages of die-casting radiators include high production efficiency (capable of producing hundreds of units per hour), tight dimensional tolerances (±0.1 mm for critical features), and the ability to integrate complex features like internal channels and mounting brackets in a single piece, reducing assembly costs. These factors make die-cast radiators indispensable for applications requiring efficient heat management, from car engines to industrial machinery and power electronics.

Read recommendations:

extruded aluminum enclosure profiles

stock aluminum extrusion profiles

How to judge whether aluminum alloy die castings are of high quality

injection moulding manufacturers.The method of deburring aluminum alloy die-casting parts

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible