2025-05-24 hits:0 source:News

In the realm of modern lighting, the energy efficiency of aluminum die - cast lighting systems has become a focal point due to the increasing demand for sustainable and cost - effective solutions. Aluminum die - casting, a manufacturing process that involves forcing molten aluminum into a mold under high pressure, plays a crucial role in enhancing the energy - saving capabilities of lighting systems.

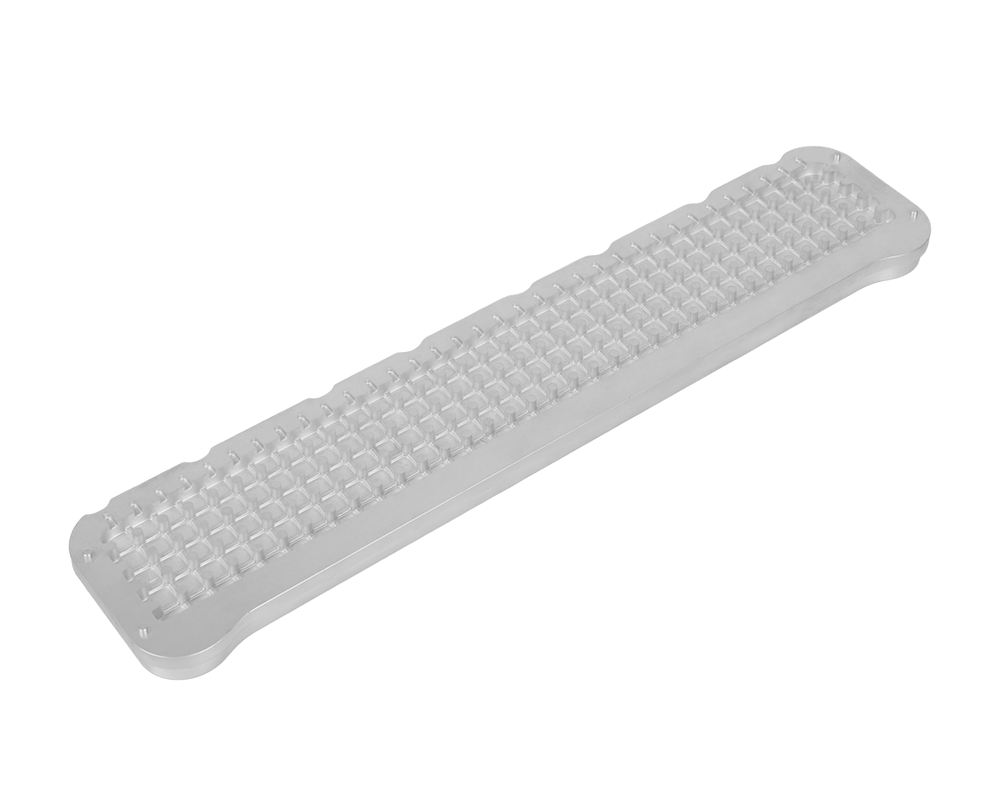

One of the primary ways aluminum die - cast lighting systems achieve energy efficiency is through superior heat dissipation. Aluminum has excellent thermal conductivity, which allows it to efficiently transfer heat away from the light - emitting diodes (LEDs), the most common light sources in modern lighting systems. In an aluminum die - cast housing, the heat generated by the LEDs can be quickly dissipated into the surrounding environment. This effective heat management prevents the LEDs from overheating, which is essential for maintaining their luminous efficacy. When LEDs overheat, their efficiency decreases, and they consume more energy to produce the same amount of light. By keeping the LEDs at an optimal operating temperature, aluminum die - cast lighting systems ensure that the LEDs can operate at peak efficiency, reducing overall energy consumption.

Moreover, the lightweight nature of aluminum die - cast components contributes to energy savings in the long run. In lighting fixtures that are installed in large numbers, such as in commercial buildings or outdoor public areas, the reduced weight of aluminum die - cast parts means lower transportation and installation costs. Less energy is required to transport and install these lighter fixtures. Additionally, in applications where the lighting system is movable or adjustable, the lightweight design allows for easier operation, reducing the energy needed for mechanical movements. For example, in some adjustable outdoor floodlights, the use of aluminum die - cast components enables smooth and energy - efficient adjustment of the light direction.

The design flexibility offered by aluminum die - casting also enables the creation of more energy - efficient lighting system structures. Designers can optimize the shape and size of the die - cast housing to improve light distribution. By incorporating reflective surfaces or specific optical designs into the aluminum die - cast parts, the light emitted by the LEDs can be directed more effectively towards the desired area, reducing light waste. This focused light distribution not only improves the lighting quality but also allows for the use of fewer LEDs or lower - power LEDs to achieve the same level of illumination, further contributing to energy savings. Additionally, the durability of aluminum die - cast lighting systems means less frequent replacement, which indirectly saves energy associated with the production, transportation, and installation of new fixtures.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible