2025-07-19 hits:0 source:News

Aluminum alloy die casting, while efficient in producing complex components, poses several environmental challenges, primarily related to energy consumption, emissions, and waste generation. However, proactive measures can mitigate these impacts, aligning production with sustainable practices.

Energy consumption is a major concern. Melting aluminum alloys requires significant energy—approximately 600 to 800 kWh per ton of aluminum. This energy is often derived from fossil fuels, leading to high carbon dioxide (CO₂) emissions, contributing to global warming. Additionally, die casting machines and auxiliary equipment (e.g., furnaces, compressors) consume large amounts of electricity, further increasing the carbon footprint. To address this, factories are increasingly adopting renewable energy sources, such as solar panels or wind turbines, to power their operations. For example, some large-scale facilities in Europe have installed solar farms that meet up to 30% of their energy needs, reducing reliance on grid electricity from fossil fuels. Waste heat recovery systems are also employed to capture excess heat from furnaces and reuse it for space heating or preheating molten metal, improving overall energy efficiency by 15-20%.

Air emissions are another critical issue. Melting and casting processes release volatile organic compounds (VOCs), particulate matter (PM), and gases like sulfur dioxide (SO₂) and nitrogen oxides (NOₓ). These pollutants contribute to air pollution, smog formation, and respiratory health problems. Factories are implementing advanced filtration systems, such as baghouses and electrostatic precipitators, to capture 99% of particulate matter. For VOCs, catalytic converters or thermal oxidizers are used to break down harmful compounds into harmless byproducts like CO₂ and water vapor. In some regions, strict emission standards (e.g., the EU’s Industrial Emissions Directive) require continuous monitoring of air quality, ensuring that emissions stay within permissible limits.

Waste generation includes leftover molten metal, defective castings, and mold release agents. Scrap aluminum from trimming and defective parts can be recycled, as aluminum retains its properties through multiple recycling cycles. Recycling aluminum consumes only 5% of the energy required to produce new aluminum from ore, making it a sustainable practice. Factories often partner with recycling facilities to ensure 90% or more of their aluminum scrap is reused. Wastewater from cleaning processes, which may contain lubricants and heavy metals, is treated in on-site wastewater treatment plants. These plants use chemical precipitation and filtration to remove contaminants, ensuring that water discharged meets environmental regulations or is reused for non-potable purposes like cooling.

Noise pollution from high-pressure die casting machines, which can exceed 90 decibels, is also a concern for workers and nearby communities. Soundproof enclosures around machines and acoustic barriers in production areas reduce noise levels to below 85 decibels, complying with occupational health and safety standards.

Read recommendations:

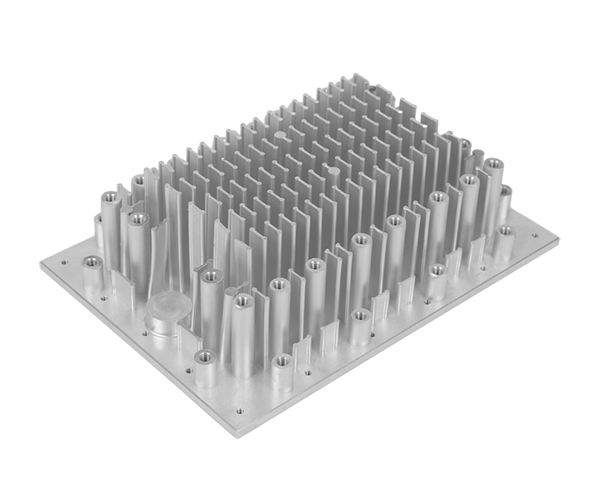

LED Cold Forged Downlight Radiator

extruded aluminum frame system

Aluminum Alloy Die Casting for Security Monitoring Enclosures

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible