2025-08-13 hits:0 source:News

High-pressure die casting equipment selection is a critical decision that directly impacts production efficiency, part quality, and long-term operational costs in die casting operations. The process involves matching machine capabilities with specific application requirements, such as material type, part size, production volume, and quality standards.

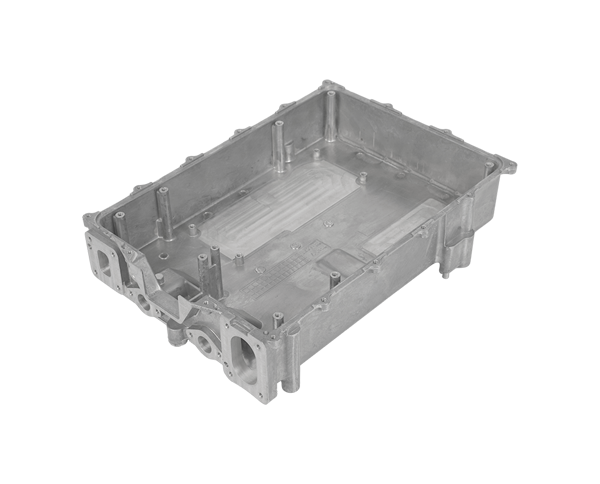

One of the primary factors to consider is the clamping force of the die casting machine, measured in tons. Clamping force must be sufficient to keep the mold closed during injection, preventing molten metal from leaking (known as flash). For small parts like automotive connectors, machines with 100-300 tons of clamping force may suffice, while large components such as engine blocks require machines with 1,000 tons or more. Calculating the required clamping force involves considering the projected area of the part (the area of the part as viewed from the direction of mold opening) multiplied by a safety factor (typically 30-50 MPa) to account for pressure variations.

Injection system performance is another key consideration. The injection unit must deliver molten metal at the correct velocity and pressure to fill the mold cavity before solidification. For non-ferrous metals like aluminum and zinc, cold chamber machines are preferred, as they handle higher melting points more effectively. Hot chamber machines, which are faster, are suitable for lower-melting-point metals like zinc and magnesium but may not be ideal for aluminum due to increased wear on components. Injection speed and pressure adjustable ranges are critical; high-speed injection (up to 10 m/s) is necessary for thin-walled parts to ensure complete filling, while lower speeds may be sufficient for thicker sections.

Machine size and workspace compatibility are also important. The machine’s footprint must fit within the production facility, with adequate space for mold changing, material handling, and maintenance. Additionally, automation integration capabilities, such as robotic part extraction or automatic mold lubrication systems, should be evaluated to enhance productivity, especially for high-volume production runs.

Energy efficiency and operating costs cannot be overlooked. Modern machines with variable-speed hydraulic pumps or electric servo systems consume less energy compared to traditional hydraulic models, reducing long-term utility expenses. Maintenance requirements and availability of spare parts are also factors, as downtime due to machine breakdowns can significantly impact production schedules.

Finally, compliance with industry standards and safety regulations is essential. Machines must meet local safety codes, including guards for moving parts and emergency stop systems, to protect operators. By carefully evaluating these factors, manufacturers can select high-pressure die casting equipment that optimizes production performance while meeting quality and cost objectives.

Read recommendations:

aluminum extrusion distributors

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible