2023-12-09 hits:0 source:News

During the assembly process, zinc alloy die castings may experience premature oxidation or moisture corrosion on the surface. The reasons include: ① deviation in various contents of the alloy, ② lack of surface protection treatment for zinc alloy die castings, and ③ damage to the surface protection layer, such as peeling off of the machining surface and coating.

The following measures can be taken to solve the problem:

1. Optoelectronic spectroscopy analysis requires strict control of chemical composition during ingredient melting, ensuring that it falls within the standard requirements and is preferably close to the median;

2. Can be shot peened or polished;

3. It is best to use the machined surface as an assembly surface. Strictly control the quality of the coating, and no peeling, peeling, or leakage defects are allowed.

Read recommendations:

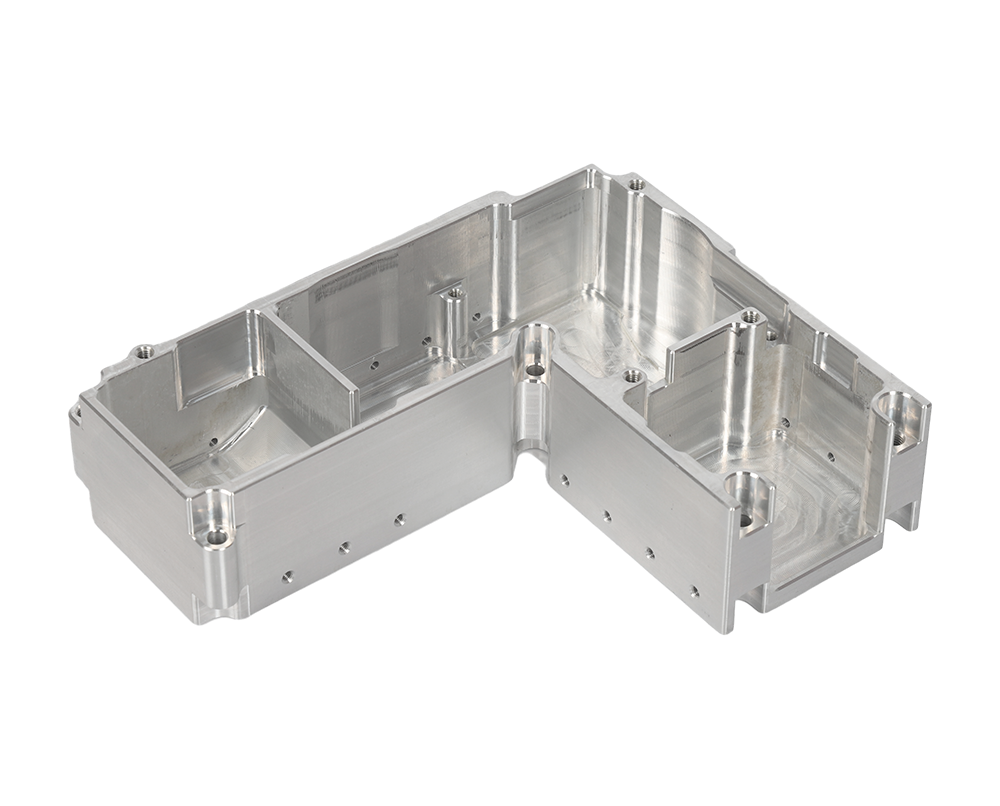

aluminium structural sections.Customized zinc alloy die castings

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible