2025-07-07 hits:0 source:News

Zinc alloy die casting has established itself as a versatile manufacturing process, finding extensive applications across multiple industries due to its unique combination of properties and cost - effectiveness.

In the automotive industry, zinc alloy die casting is widely used for producing various components. Interior trim parts, such as door handles, knobs, and decorative accents, benefit from the excellent surface finish and intricate detail that zinc alloy die casting can achieve. These parts not only enhance the aesthetic appeal of the vehicle but also provide functional durability. Externally, components like mirror housings and some small - scale structural brackets are often made through zinc alloy die casting. The material's good mechanical properties, including strength and toughness, make it suitable for withstanding the rigors of automotive use. Moreover, zinc alloy's relatively low melting point reduces energy consumption during the casting process, aligning with the automotive industry's focus on cost - control and environmental sustainability.

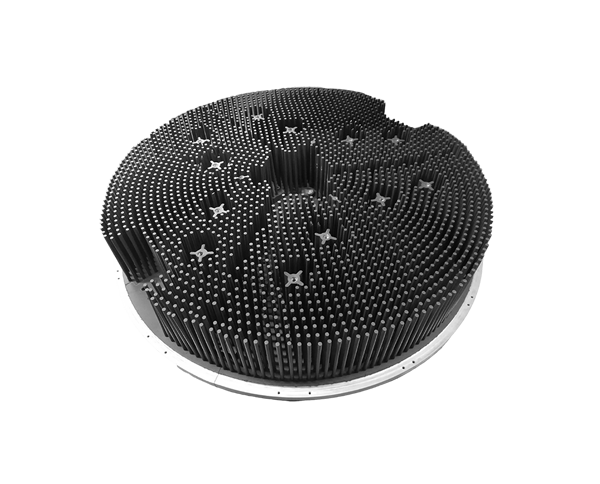

The electronics industry also relies heavily on zinc alloy die casting. With the continuous miniaturization of electronic devices, the demand for precision - made components is high. Zinc alloy is used to manufacture casings for various electronic products, such as smartphones, tablets, and laptops. These casings offer protection against physical damage, electromagnetic interference, and also contribute to the overall design aesthetics. The high - precision nature of die casting allows for the integration of complex features, such as ports, buttons, and ventilation holes, directly into the component during the casting process. Additionally, zinc alloy's good heat - dissipation properties make it suitable for applications where managing the heat generated by electronic components is crucial, such as in power supply units and high - performance computing devices.

In the furniture and hardware sectors, zinc alloy die casting is commonly employed for producing high - quality decorative and functional hardware. Cabinet handles, drawer pulls, and hinges made from zinc alloy combine durability with an attractive appearance. The ability to create a wide range of surface finishes, from polished chrome - like effects to antique - looking patinas, makes zinc alloy hardware highly desirable for both residential and commercial furniture applications. In the construction industry, zinc alloy die - cast components are used in architectural hardware, such as door locks, window fittings, and curtain rod brackets. Their corrosion resistance ensures long - term performance, even in outdoor or humid environments.

Furthermore, the toy industry frequently utilizes zinc alloy die casting for producing high - end collectible toys and action figures. The process enables the creation of detailed and intricate designs, replicating the fine features of characters or vehicles. The strength of zinc alloy also ensures that these toys can withstand rough handling, making them suitable for both play and display purposes.

Read recommendations:

aluminium profile for glass railing

80 20 aluminum extrusion profiles

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible