2025-07-24 hits:0 source:News

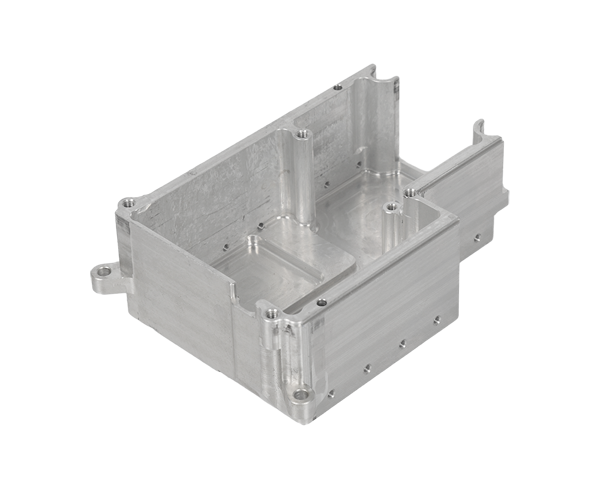

Optimizing die casting processes to increase productivity involves a combination of technological advancements, process refinements, and data-driven adjustments, all aimed at reducing cycle times, minimizing defects, and maximizing machine utilization. One key method is the optimization of injection parameters: fine-tuning variables such as injection speed, pressure, and metal temperature can significantly reduce cycle times while maintaining part quality. For example, using adaptive control systems that automatically adjust injection speed based on real-time feedback (e.g., pressure sensors in the die) ensures consistent filling of the mold cavity, reducing the need for manual adjustments and minimizing scrap.

Mold design improvements also play a vital role. Incorporating features like efficient cooling channels ensures faster solidification of the molten metal, reducing the time the part remains in the die. Advanced mold materials, such as heat-resistant alloys or coated steels, extend mold life and reduce maintenance downtime. Additionally, using modular molds that allow for quick changeovers enables manufacturers to switch between part designs in minutes rather than hours, increasing machine uptime and flexibility.

Automation is another critical factor in boosting productivity. Integrating robotic systems for tasks like part ejection, trimming, and inspection reduces manual labor, speeds up production cycles, and minimizes human error. Robots can operate 24/7, increasing overall equipment effectiveness (OEE) and enabling lights-out manufacturing. Real-time monitoring systems, using sensors to track variables like die temperature, pressure, and cycle time, provide valuable data that can be analyzed to identify bottlenecks. For example, if a machine consistently experiences longer cycle times during afternoon shifts, adjustments to cooling system performance or operator training can be implemented.

Material management optimization, such as using preheated alloy materials to reduce melting time, and implementing just-in-time (JIT) delivery of raw materials, minimizes inventory holding costs and reduces production delays. Regular preventive maintenance of die casting machines, including lubrication of moving parts and calibration of sensors, prevents unexpected breakdowns and ensures consistent performance. By combining these methods—parameter optimization, advanced mold design, automation, data-driven monitoring, and proactive maintenance—manufacturers can achieve significant increases in productivity, often by 20–30%, while maintaining or improving part quality.

Read recommendations:

rectangular aluminum extrusion profiles

custom steel plate fabrication

spiral duct fabrication.Production of Zinc Alloy Die Castings

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible