2025-06-11 hits:0 source:News

The design of common alloy die - casting molds plays a pivotal role in determining the quality, efficiency, and cost - effectiveness of the die - casting process. Optimization of these molds involves a comprehensive consideration of multiple factors, including mold structure, material selection, cooling system design, and gating system configuration.

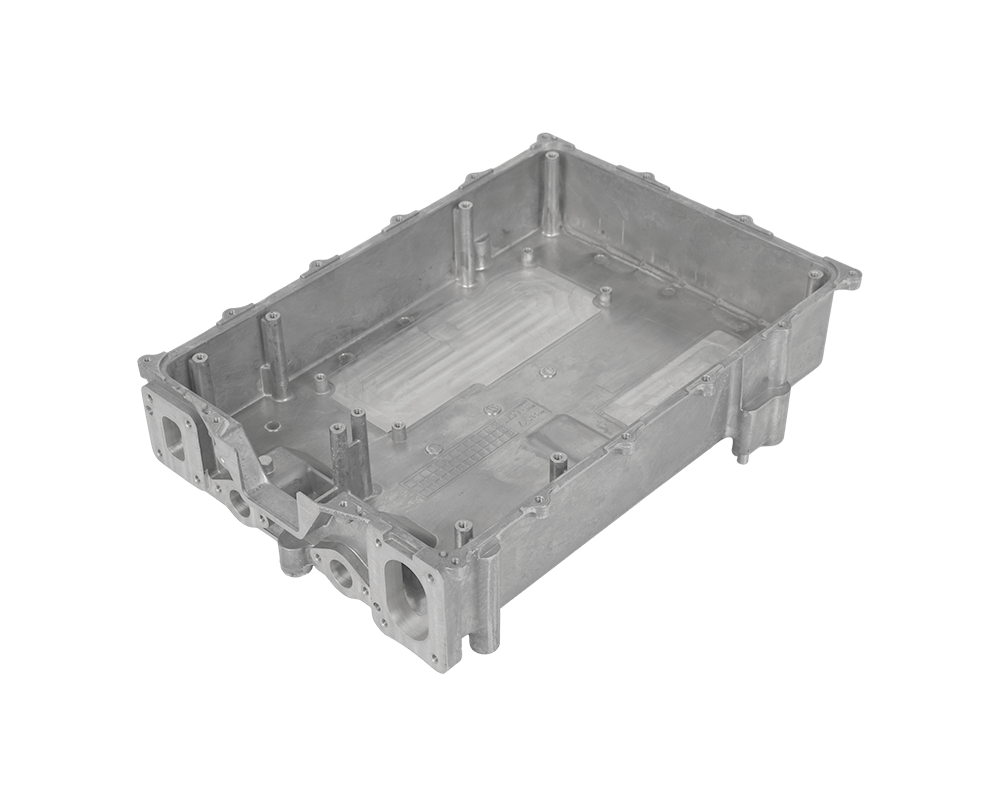

Mold structure design is the foundation of optimization. The mold should be designed with a rational parting surface to ensure easy demolding of the castings while minimizing the formation of flash. The core - cavity structure needs to be carefully planned to accurately form the complex geometries of the cast parts. For example, in the design of molds for parts with undercuts, side - core - pulling mechanisms should be incorporated. These mechanisms can be designed as hydraulic, pneumatic, or mechanical types, depending on the specific requirements of the casting. By optimizing the mold structure, the number of mold components can be reduced, simplifying the manufacturing process and reducing costs.

Material selection for die - casting molds is crucial. Common alloy die - casting molds are usually made of high - quality tool steels, such as H13 steel. H13 steel offers excellent thermal fatigue resistance, hardness, and toughness, which are essential for withstanding the high - temperature and high - pressure conditions during the die - casting process. However, the selection of the specific grade and heat - treatment process of the steel should be optimized based on the alloy type being cast, the casting cycle, and the expected mold life. Advanced materials, such as hot - work die - casting steels with improved corrosion resistance or new composite materials, are also being explored to further enhance mold performance.

The cooling system design is another key aspect of mold optimization. An efficient cooling system can significantly reduce the cycle time of the die - casting process and improve the surface quality of the castings. Cooling channels should be strategically placed within the mold to ensure uniform cooling of the mold surfaces in contact with the molten alloy. Modern mold design often utilizes computer - aided engineering (CAE) software to simulate the cooling process and optimize the layout of the cooling channels. For example, conformal cooling channels, which follow the contours of the mold cavity, can provide more uniform cooling compared to traditional straight - line channels, reducing the risk of thermal deformation and improving the dimensional accuracy of the castings.

The gating system configuration also requires optimization. The gating system is responsible for the smooth flow of the molten alloy into the mold cavity. By optimizing the size, shape, and location of the gates, runners, and sprues, the filling time can be minimized, and the occurrence of casting defects, such as air entrapment and shrinkage porosity, can be reduced. For example, using a multi - gate system can improve the filling balance of large - sized castings, while a fan - shaped gate can help in the uniform filling of thin - walled parts.

Read recommendations:

aluminum electronic enclosures boxes

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible