2025-06-06 hits:0 source:News

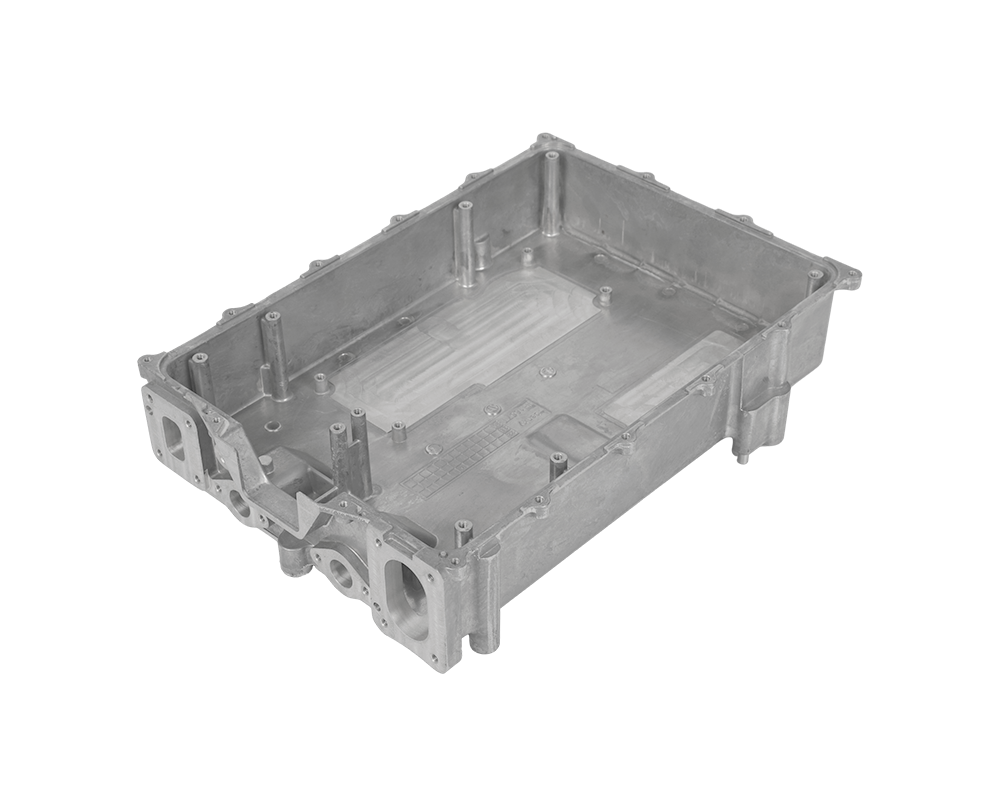

Ordinary alloy die - casting for furniture hardware is a crucial manufacturing process that combines the advantages of various alloys to produce durable, functional, and aesthetically pleasing components for furniture. This process plays a significant role in enhancing the overall quality and performance of furniture products.

The choice of alloys is fundamental in furniture hardware die - casting. Common alloys used include zinc - based alloys, aluminum - based alloys, and magnesium - based alloys. Zinc - based alloys are widely favored due to their excellent casting properties, such as low melting point, high fluidity, and good dimensional stability. These characteristics allow for the production of complex - shaped furniture hardware with high precision, including handles, hinges, and drawer slides. Zinc - based alloy castings also have good surface finish quality, which can be easily polished, electroplated, or painted to achieve various decorative effects, enhancing the aesthetic appeal of furniture.

Aluminum - based alloys are another popular option for furniture hardware die - casting. They offer a high strength - to - weight ratio, making the hardware components lightweight yet sturdy. Aluminum castings are also highly resistant to corrosion, which is essential for furniture used in different environments, especially those with high humidity. This corrosion resistance ensures the long - term durability of the hardware, reducing the need for frequent replacements. Additionally, aluminum can be anodized to create a hard, protective oxide layer on the surface, further enhancing its corrosion resistance and providing a variety of color options for customization.

The die - casting process for furniture hardware involves several key steps. First, a mold is designed and fabricated according to the specific requirements of the hardware component. The mold is typically made of high - quality tool steel and is precisely machined to ensure accurate replication of the desired shape. Molten alloy is then injected into the mold cavity under high pressure using a die - casting machine. After the alloy solidifies, the mold is opened, and the cast part is ejected. Post - processing operations, such as trimming, deburring, and surface treatment, are carried out to refine the shape, remove any excess material, and improve the surface quality of the hardware.

In the furniture industry, the quality of hardware components directly affects the functionality and lifespan of furniture. Well - made die - cast furniture hardware not only provides reliable mechanical support but also adds to the overall value and marketability of the furniture. Manufacturers need to pay close attention to every aspect of the alloy die - casting process, from alloy selection to quality control, to ensure that the produced hardware meets high - standard requirements.

Read recommendations:

channel aluminum extrusion profiles

aluminum heatsink extrusion profiles

Aluminum Alloy Die Casting for Security Monitoring Enclosures

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible