2025-07-16 hits:0 source:News

The process of pure aluminum die casting for small - sized motor shells is a complex and precise manufacturing technique that combines the unique properties of pure aluminum with advanced die - casting methods. Pure aluminum is highly favored for motor shell production due to its excellent thermal conductivity, lightweight nature, and good corrosion resistance, which are essential for the performance and durability of small motors.

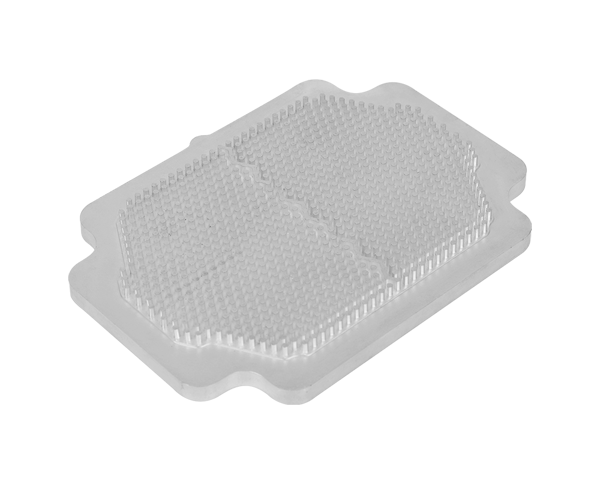

The first step in the process is mold design and fabrication. Using computer - aided design (CAD) software, engineers create detailed 3D models of the motor shell, taking into account factors such as size, shape, wall thickness, and internal features. The mold, typically made of high - strength tool steel, consists of two halves: the cavity side and the core side. Precision machining techniques, including computer - numerical control (CNC) milling and electrical discharge machining (EDM), are employed to fabricate the mold with high accuracy, ensuring that the final motor shell meets the required specifications.

Once the mold is ready, the pure aluminum is melted in a furnace. Specialized melting furnaces are used to heat the aluminum to its melting point, usually around 660°C (1220°F). During the melting process, careful control of temperature and the addition of appropriate alloying elements (even for pure aluminum, small amounts of additives might be used to improve casting properties) are crucial. This helps to ensure the purity and fluidity of the molten aluminum, which directly affects the quality of the casting.

Next, the molten aluminum is injected into the mold under high pressure. High - pressure die - casting machines, capable of generating pressures ranging from 15 to 100 megapascals, are used for this purpose. The high - pressure injection ensures that the molten aluminum fills the mold cavity completely and rapidly, capturing all the fine details of the design. After the injection, a short holding time is applied to ensure that any shrinkage within the casting is compensated for by additional molten metal flow.

Once the aluminum has solidified within the mold, the mold is opened, and the cast motor shell is ejected. However, the process doesn't end here. Post - processing operations are often required. These may include trimming to remove any excess material, such as flash or gates, from the casting. Machining operations like drilling, tapping, and milling are also carried out to create holes, threads, and other precise features required for the assembly of the motor components. Surface finishing techniques, such as polishing, anodizing, or powder coating, are applied to enhance the appearance, corrosion resistance, and wear resistance of the motor shell. Throughout the entire process, quality control measures are implemented at every stage, including visual inspection, dimensional measurement, and non - destructive testing, to ensure that the final product meets the strict quality standards for small - sized motor shells.

Read recommendations:

aluminium extrusion automotive

aluminum extrusion linear rail

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible