2025-05-23 hits:0 source:News

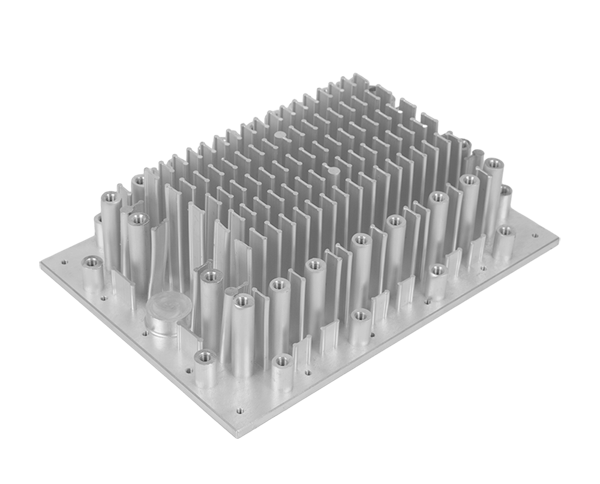

Design of High-Precision Molds for Pure Aluminum Die-Casting

The design of high-precision molds for pure aluminum die-casting is a complex and critical process that significantly influences the quality, dimensional accuracy, and production efficiency of die-cast components. Pure aluminum, known for its lightweight, good thermal conductivity, and excellent formability, is widely used in various industries. However, achieving high precision in die-casting with pure aluminum requires meticulous mold design.

The first step in mold design is to understand the requirements of the final product. This involves analyzing the part's geometry, dimensional tolerances, surface finish, and mechanical properties. Using computer-aided design (CAD) software, designers create a 3D model of the part, which serves as the basis for mold design. The mold design must consider factors such as the part's draft angles, wall thicknesses, and rib configurations to ensure proper filling of the mold cavity during the die-casting process and easy ejection of the cast part.

For high-precision molds, the selection of mold materials is crucial. High-quality tool steels, such as H13 steel, are commonly used due to their high hardness, wear resistance, and good thermal conductivity. These properties help maintain the mold's dimensional stability during the high-temperature and high-pressure die-casting process. The mold's parting surfaces, where the two halves of the mold meet, need to be designed with extreme precision to prevent flash formation, which can affect the part's dimensional accuracy and surface finish.

The gating system design is another important aspect. The gating system controls the flow of molten pure aluminum into the mold cavity. It includes components such as the sprue, runners, and gates. A well-designed gating system ensures uniform filling of the cavity, minimizes turbulence, and reduces the formation of air bubbles and voids in the cast part. For high-precision applications, the gates are often designed to be small and precisely located to control the flow rate and direction of the molten metal.

Cooling channels are also an essential part of high-precision mold design. Effective cooling is necessary to control the solidification process of the pure aluminum, ensuring consistent dimensional accuracy and reducing the risk of warping and distortion. The cooling channels are strategically placed within the mold to achieve uniform cooling of the mold cavity. Computer-aided engineering (CAE) simulations are often used to optimize the cooling channel layout, predicting the temperature distribution and solidification behavior of the molten aluminum.

In addition, the ejection system of the mold needs to be carefully designed. The ejection system is responsible for removing the solidified part from the mold cavity. It should be designed to apply uniform force to the part to prevent damage during ejection. High-precision molds may use advanced ejection mechanisms, such as stripper plates or ejector pins with precise positioning, to ensure the part is ejected smoothly and without deformation. Overall, the design of high-precision molds for pure aluminum die-casting requires a comprehensive understanding of material properties, die-casting processes, and advanced design techniques to produce high-quality, dimensionally accurate components.

Read recommendations:

t slot 2020 aluminum extrusion

aluminum radius corner extrusion

t slot aluminum extrusion profiles

What to do if there is a hard problem in aluminum alloy die-casting parts.8020 extruded

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible