2025-06-20 hits:0 source:News

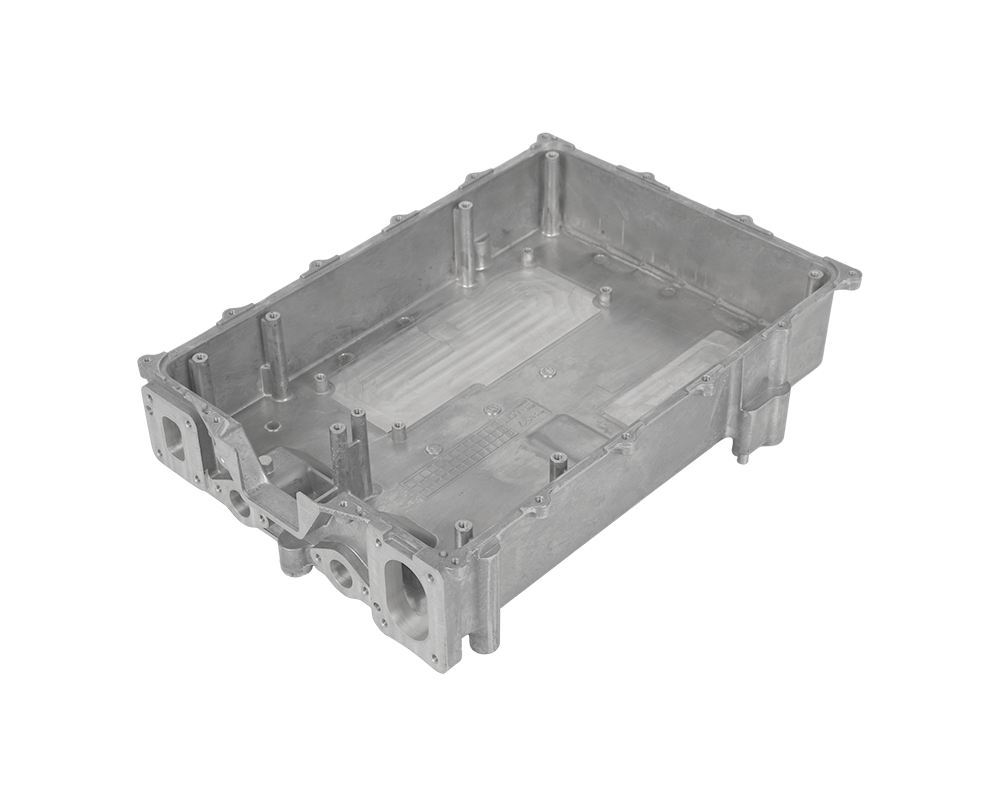

Pure aluminum die casting has emerged as a crucial manufacturing technique for environmental protection equipment, offering a combination of lightweight, high - strength, and corrosion - resistant properties that are highly suitable for the demanding operating conditions of such equipment.

In environmental protection equipment, components often need to withstand exposure to various corrosive substances, including chemicals, moisture, and pollutants. Pure aluminum, with its natural ability to form a thin, protective oxide layer upon contact with air, provides excellent corrosion resistance. This characteristic ensures that parts such as housings, frames, and fluid - handling components in wastewater treatment plants, air purification systems, and waste incinerators can maintain their structural integrity over long periods. For example, in wastewater treatment facilities, aluminum - die - cast components can resist the corrosive effects of acidic and alkaline wastewater, reducing the need for frequent replacements and minimizing maintenance costs.

The die - casting process itself enables the production of complex geometries with high precision. For environmental protection equipment, which often requires components with intricate internal channels for fluid flow or ventilation, pure aluminum die casting can accurately create these features. Advanced die - casting machines can achieve tight tolerances, ensuring that parts fit together seamlessly, which is essential for preventing leaks in systems that handle hazardous materials. Additionally, the lightweight nature of aluminum reduces the overall weight of the equipment, making it easier to transport and install. This is particularly beneficial for large - scale environmental projects where mobility and ease of setup are important considerations. Quality control in pure aluminum die casting for environmental protection equipment involves strict inspection procedures. Non - destructive testing methods, such as X - ray and ultrasonic inspections, are used to detect internal defects like porosity or cracks. Surface finish inspections are also carried out to ensure that components meet the required standards for corrosion resistance and aesthetic appeal.

Read recommendations:

aluminium profile for kitchen cabinets

c beam aluminum extrusion.Cold insulation for casting processing tips

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible