2025-08-09 hits:0 source:News

The simulation of die casting filling path is a advanced engineering technique that uses computational fluid dynamics (CFD) and finite element analysis (FEA) to model the flow of molten metal through the mold cavity, predicting potential defects and optimizing the filling process. This virtual testing method allows engineers to visualize how the molten metal fills the mold, identify areas of turbulence, air entrapment, or incomplete filling, and make design adjustments before producing physical prototypes, reducing development time and costs.

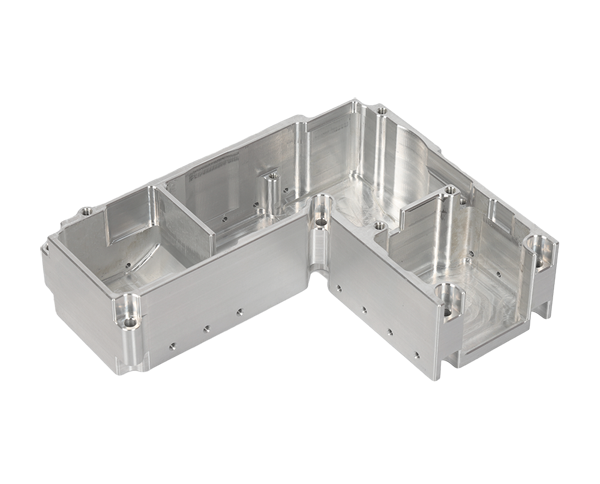

The filling path simulation begins with the creation of a 3D model of the mold cavity, including the gate, runners, risers, and any other features that influence the flow of molten metal. This model is then used to simulate the entire filling process, from the moment the molten metal is injected into the mold until the cavity is completely filled. The simulation software calculates key parameters such as flow velocity, pressure distribution, temperature gradients, and air entrapment, providing a detailed analysis of the filling behavior.

One of the primary benefits of filling path simulation is the ability to predict and prevent defects. For example, if the simulation shows that two flow fronts meet in a certain area of the mold cavity, it may indicate the formation of a cold shut, a defect where the molten metal does not properly fuse together. By adjusting the gate location or size, engineers can alter the filling path to ensure that the flow fronts merge correctly, eliminating the cold shut. Similarly, simulations can identify areas where air is trapped, which can lead to porosity in the casting, allowing for the addition of vents or changes in gate design to release the trapped air.

Flow velocity is a critical parameter in filling path simulation. The molten metal must flow at a velocity that is high enough to fill the mold cavity before solidification starts but not so high that it causes turbulence. Turbulent flow can lead to oxide formation, air entrapment, and erosion of the mold surface. Simulation software helps determine the optimal velocity by analyzing the viscosity of the molten metal, the geometry of the mold cavity, and the injection pressure. For example, in thin-walled parts, higher velocities may be required to ensure complete filling, while thick-walled parts may need lower velocities to prevent turbulence.

Temperature distribution is another important factor analyzed in filling path simulation. The molten metal loses heat as it comes into contact with the cool mold walls, and uneven cooling can lead to inconsistent solidification. Simulations track the temperature of the molten metal as it flows through the mold, identifying areas where cooling is too rapid, which can cause premature solidification and incomplete filling. This information is used to optimize the mold’s cooling system, such as adding or adjusting cooling channels, to ensure uniform cooling and proper filling.

Filling path simulation also helps in optimizing the design of the runner system, which distributes the molten metal from the gate to the mold cavity. By analyzing the flow through the runners, engineers can ensure that the molten metal reaches all parts of the cavity at the same time, preventing uneven filling. This is particularly important for multi-cavity molds, where the runner system must be balanced to ensure that each cavity fills uniformly.

In addition to these benefits, filling path simulation allows for the testing of different scenarios without the need for physical molds, saving time and resources. Engineers can simulate the effect of changing gate location, runner size, or injection parameters, quickly identifying the optimal design. This iterative process leads to a more robust die casting process with fewer defects and higher production efficiency.

the simulation of die casting filling path is a powerful tool that enhances the design and production of die cast parts. By providing detailed insights into the flow behavior of molten metal, it enables engineers to optimize the mold design, prevent defects, and improve the quality and efficiency of the die casting process.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible