2024-01-12 hits:0 source:News

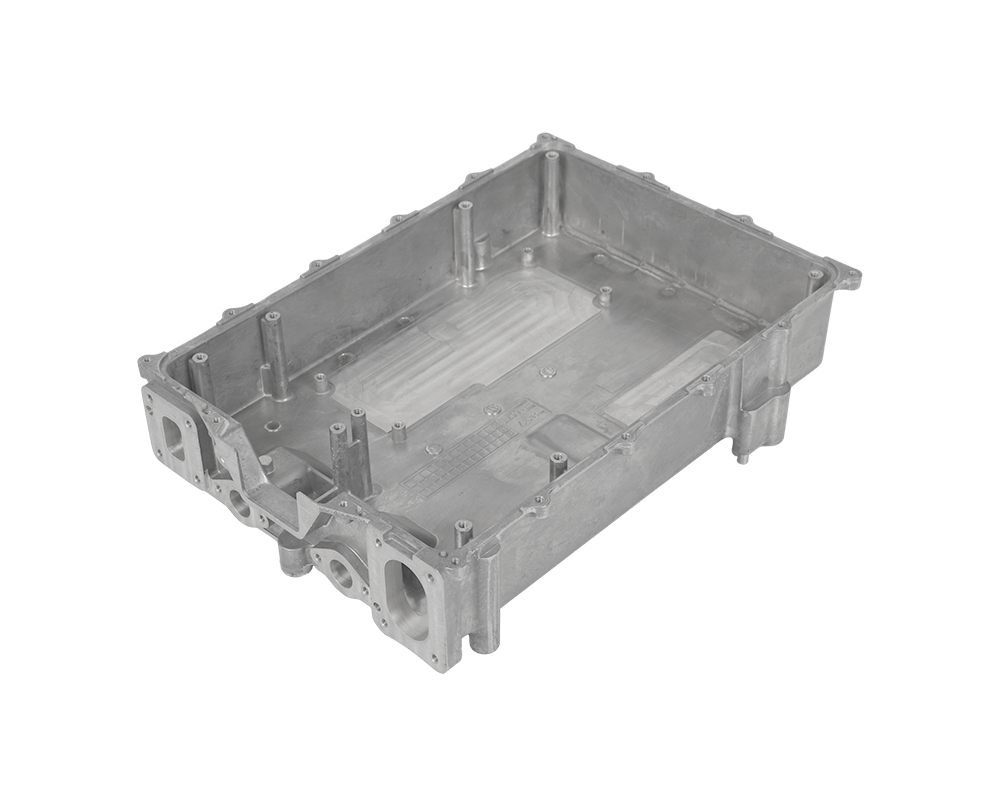

Aluminum alloy die-casting parts are applied in various industries, and the market demand is huge. However, in the production process, aluminum alloy die-casting parts are prone to shrinkage problems. Today, aluminum alloy die-casting factories will explain the reasons and solutions for this problem.

Shrinkage is a hole caused by insufficient internal compensation during the condensation process of die castings, and the reasons are as follows

① Pouring temperature too high

② Low injection pressure

③ Castings have areas or sections with significant metal accumulation or changes in cross-section on the structure

④ Small inner gate

Solution to shrinkage

① Change the structure of castings, eliminate metal aggregation and significant cross-sectional changes

② Reduce the pouring temperature under possible conditions

③ Increase injection pressure

④ Properly improve the pouring system to better transmit pressure

Read recommendations:

aluminium die casting auto parts

stamped metal parts manufacturer.Zinc die castings are not equivalent to zinc alloy die castings

Why is the minimum order quantity set so high for customized aluminum alloy die-casting

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible