2025-06-13 hits:0 source:News

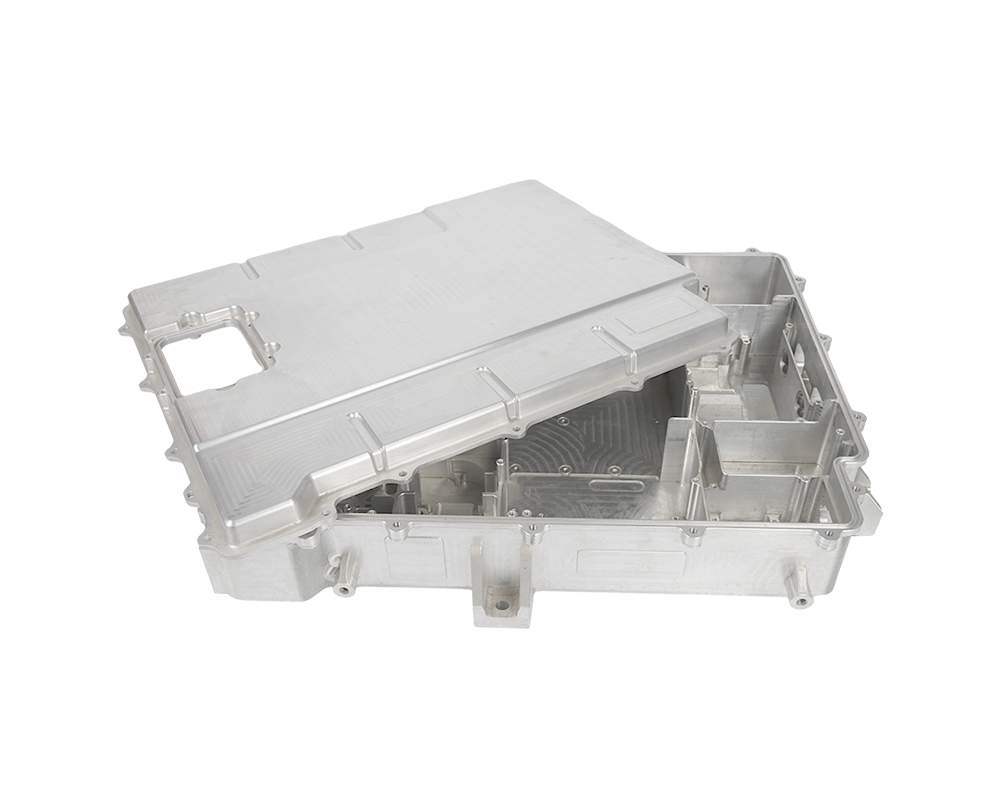

The waterproof performance of aluminum die - castings is of utmost importance, especially for components used in outdoor or humid environments. To achieve excellent waterproofing, several factors need to be considered during the design and manufacturing process.

Firstly, the design of the aluminum die - casting itself plays a crucial role. Properly designed seals and gaskets are essential for preventing water ingress. The housing should be designed with grooves or channels to accommodate seals, ensuring a tight fit when the different parts of the casting are assembled. The shape and dimensions of these sealing areas need to be carefully calculated to ensure that the seals can effectively block water penetration. Additionally, the use of o - rings or other types of elastomeric seals made from materials with good water resistance, such as silicone or neoprene, is common. These seals are compressed between mating surfaces of the aluminum die - casting, creating a barrier against water.

Secondly, the quality of the die - casting process affects waterproof performance. A well - executed die - casting process results in a casting with minimal porosity and surface defects. Porosity, which refers to the presence of small voids or holes within the casting, can provide pathways for water to enter. Advanced die - casting techniques, as mentioned earlier, can reduce porosity significantly. After the die - casting is completed, post - processing treatments such as shot peening or impregnation can further enhance the surface integrity and waterproofing ability. Shot peening compresses the surface layer of the casting, closing up any micro - cracks or pores, while impregnation fills the pores with a sealant material.

Finally, surface finishing also contributes to waterproofing. Applying a protective coating, such as a powder coat or an epoxy paint, to the aluminum die - casting creates an additional layer of protection against water. These coatings not only prevent direct contact between the aluminum and water but also offer resistance to corrosion, which can weaken the casting over time and compromise its waterproof properties. Regular inspection and maintenance of the coated surface are necessary to ensure that there are no scratches or damages that could allow water to penetrate.

Read recommendations:

40 x 40 aluminium profile price

Aluminum Alloy T-slot Miter Track

corten steel fabricators near me.Four major factors affecting the quality of die-casting processing

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible