2025-06-23 hits:0 source:News

Zinc alloy die casting is a widely used manufacturing process known for its efficiency and ability to produce complex, high - quality parts.

1. Alloy Preparation

Zinc alloy is a combination mainly composed of zinc, along with other elements such as aluminum, magnesium, and copper. These additional elements are added to enhance the alloy's mechanical properties. For example, aluminum improves strength and corrosion resistance, magnesium helps in grain refinement, and copper increases hardness. First, the raw materials are carefully weighed according to the specific alloy composition requirements. Then, they are melted in a furnace. The melting temperature for zinc alloys is relatively low compared to some other metals, typically around 400 - 450 °C for common zinc - based alloys like Zamak 3. This low melting point is an advantage as it reduces energy consumption during the melting process.

2. Mold Design and Fabrication

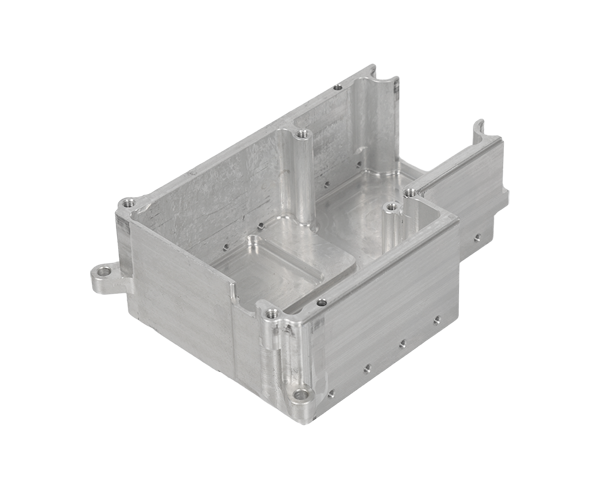

The mold, also called a die, is crucial in determining the final shape of the zinc alloy casting. Mold designers create a 3D model of the part using computer - aided design (CAD) software. The mold is designed with two halves: a stationary half and a movable half. Cavities, cores, and runners are designed within the mold. Cavities are the spaces where the molten zinc alloy will solidify to form the desired part shape. Cores are used to create internal features such as holes. Runners are channels that direct the flow of molten metal from the injection point to the cavities. The mold is typically made of high - strength steel to withstand the high pressure and temperature during the die - casting process. After the design is complete, the mold is fabricated using precision machining techniques, including milling, drilling, and electrical discharge machining (EDM) for complex shapes.

3. Die - Casting Machine Setup

There are two main types of die - casting machines for zinc alloys: hot chamber and cold chamber. For zinc alloy, hot chamber die - casting machines are more commonly used due to the alloy's relatively low melting point. In a hot chamber die - casting machine, the furnace is an integral part of the machine. The molten zinc alloy is stored in the furnace. The machine has a gooseneck, which is submerged in the molten metal. A plunger or piston is used to inject the molten metal into the mold cavity. Before starting the production, the die - casting machine needs to be properly set up. This includes adjusting the injection pressure, which usually ranges from 700 - 5000 psi (5 - 35 MPa), the injection speed, and the hold - time (the time the pressure is maintained on the molten metal in the mold).

4. Injection and Solidification

Once the machine is set up, the molten zinc alloy is injected into the mold cavity. The plunger in the hot chamber die - casting machine moves downward, forcing the molten metal through the gooseneck and nozzle into the mold. The high pressure ensures that the molten metal fills every part of the mold cavity, replicating the intricate details of the mold. After injection, the molten metal begins to solidify. The cooling time depends on the size and thickness of the casting. Generally, it can range from a few seconds to several minutes. During this time, the casting shrinks slightly as it cools. To ensure uniform cooling and prevent defects such as warping, cooling channels are often built into the mold, through which a cooling medium (usually water) circulates.

5. Ejection and Trimming

When the casting has solidified sufficiently, the mold halves open. Ejection pins in the movable half of the mold push the solidified casting out of the mold cavity. After ejection, the casting may have some excess material, such as runners and gates (the parts of the casting that were used to feed the molten metal into the cavity). These are removed through a trimming process. Trimming can be done using mechanical shears, saws, or in some cases, by using a secondary machining operation.

6. Finishing Operations

The as - cast zinc alloy parts may require further finishing operations. This can include polishing to improve the surface finish. Polishing can be done in multiple steps, starting with rough polishing to remove any surface imperfections, followed by fine polishing to achieve a smooth, shiny surface. Other finishing operations may include plating (such as zinc plating, nickel plating, or chrome plating) to enhance corrosion resistance and appearance, or painting for decorative purposes.

Read recommendations:

extruded aluminum pcb enclosure

extruded aluminum stair nosing

Advantages of Aluminum Alloy Die - Casting Products

Bubble formation after zinc alloy die-casting electroplating

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible