2025-05-30 hits:0 source:News

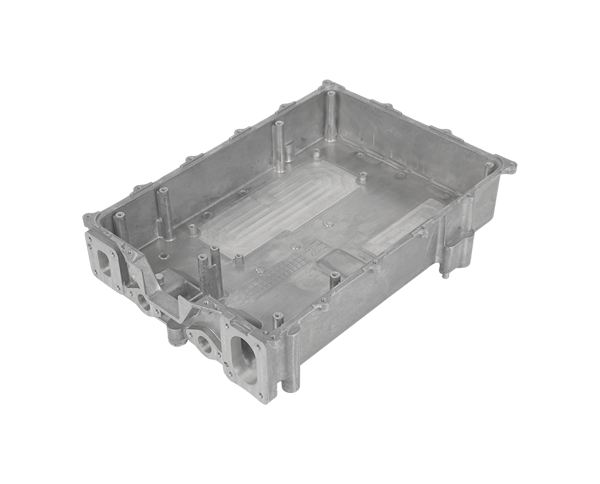

The aluminum die - casting production manufacturing process is a complex and highly organized sequence of steps aimed at creating high - quality aluminum components with precise shapes and dimensions. This process begins with the preparation of raw materials. High - purity aluminum alloy ingots are selected as the base material. These ingots are typically composed of aluminum along with alloying elements such as silicon, magnesium, copper, or zinc, which are added to enhance specific properties like strength, hardness, and fluidity.

The next crucial stage is melting the aluminum alloy. The ingots are loaded into a melting furnace, which is usually fueled by natural gas, electricity, or oil. Inside the furnace, the temperature is carefully controlled to reach the melting point of the specific alloy, typically ranging from 600°C to 750°C. Once melted, the molten aluminum is held at a suitable temperature to ensure proper fluidity for casting. During this stage, degassing and fluxing operations may be carried out. Degassing removes hydrogen and other dissolved gases from the molten metal to prevent porosity in the final casting, while fluxing helps to remove impurities and oxides from the surface of the molten aluminum.

After the molten aluminum is prepared, it is transferred to the die - casting machine. Die - casting machines consist of two main parts: the injection unit and the clamping unit. The injection unit forces the molten aluminum into the die cavity under high pressure, usually ranging from 15 to 100 megapascals (MPa). The clamping unit holds the die halves firmly together to withstand the high injection pressure and prevent any leakage of the molten metal. The die itself is a precision - engineered mold made of high - strength tool steel. It consists of two halves, the cavity and the core, which form the shape of the desired aluminum component.

Once the molten aluminum is injected into the die cavity, it solidifies rapidly as it comes into contact with the relatively cool die surfaces. This rapid solidification process helps to create a fine - grained microstructure in the casting, which contributes to its mechanical properties. After solidification, the die - casting machine opens, and the cast aluminum part is ejected using ejector pins. However, the process doesn't end here. The cast part usually has excess material in the form of runners, gates, and flash, which are removed through trimming operations. Trimming can be done using hydraulic or mechanical presses with specialized cutting tools.

Finally, the aluminum castings may undergo further post - processing operations such as heat treatment, surface finishing, and quality inspection. Heat treatment can improve the mechanical properties of the casting by altering its microstructure. Surface finishing methods like polishing, anodizing, or powder coating are used to enhance the appearance and corrosion resistance of the part. Quality inspection involves various techniques such as dimensional measurement, non - destructive testing (e.g., X - ray, ultrasonic testing) to ensure that the castings meet the required specifications.

Read recommendations:

There is a saying about the thickness of the "skin" of aluminum alloy die-casting parts

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible