2025-05-13 hits:0 source:News

Aluminum die - castings have become an integral part of the fingerprint recognition technology in smart door locks, playing a crucial role in enhancing the functionality, durability, and user experience of these advanced security devices.

In the context of fingerprint recognition in smart door locks, the aluminum die - casting process offers several advantages. Firstly, the high precision and complexity of the die - casting process allow for the creation of intricate and precise components that house the fingerprint sensor and related electronic modules. The sensor module, which is the core of fingerprint recognition, requires a stable and protective housing. Aluminum die - castings can be designed to have exacting dimensions, ensuring a snug fit for the sensor, minimizing any potential movement or misalignment that could affect the accuracy of fingerprint scanning.

The mechanical properties of aluminum die - castings contribute significantly to the overall performance of fingerprint - enabled smart door locks. Aluminum alloys used in die - casting possess excellent strength - to - weight ratios. This means that the components made from these alloys are robust enough to withstand external impacts, such as accidental bumps or attempts at forced entry, while remaining relatively lightweight. A sturdy housing is essential for protecting the delicate fingerprint sensor from physical damage, which could lead to inaccurate readings or complete failure of the recognition system.

Furthermore, the surface finish of aluminum die - castings can be optimized to enhance the fingerprint recognition process. Special surface treatments, such as anodizing or powder coating, can be applied to the die - cast components. Anodizing not only improves the corrosion resistance of the aluminum but also provides a smooth and non - porous surface. This smooth surface helps prevent the accumulation of dirt, oil, and other contaminants that could interfere with the fingerprint sensor's ability to accurately capture and analyze fingerprint patterns. Powder coating, on the other hand, offers a wide range of color options and a durable finish, allowing for aesthetic customization while maintaining the necessary surface characteristics for reliable fingerprint recognition.

In addition to physical protection and surface optimization, aluminum die - castings also play a role in the electrical shielding of the fingerprint recognition module. The conductive nature of aluminum can be utilized to create electromagnetic shielding, reducing interference from external electromagnetic sources. This is crucial as electromagnetic interference can disrupt the electrical signals within the fingerprint sensor, leading to false negatives or positives in the recognition process. By effectively shielding the sensor, aluminum die - castings contribute to the consistent and accurate operation of the fingerprint recognition technology in smart door locks, providing users with a secure and convenient access solution.

Read recommendations:

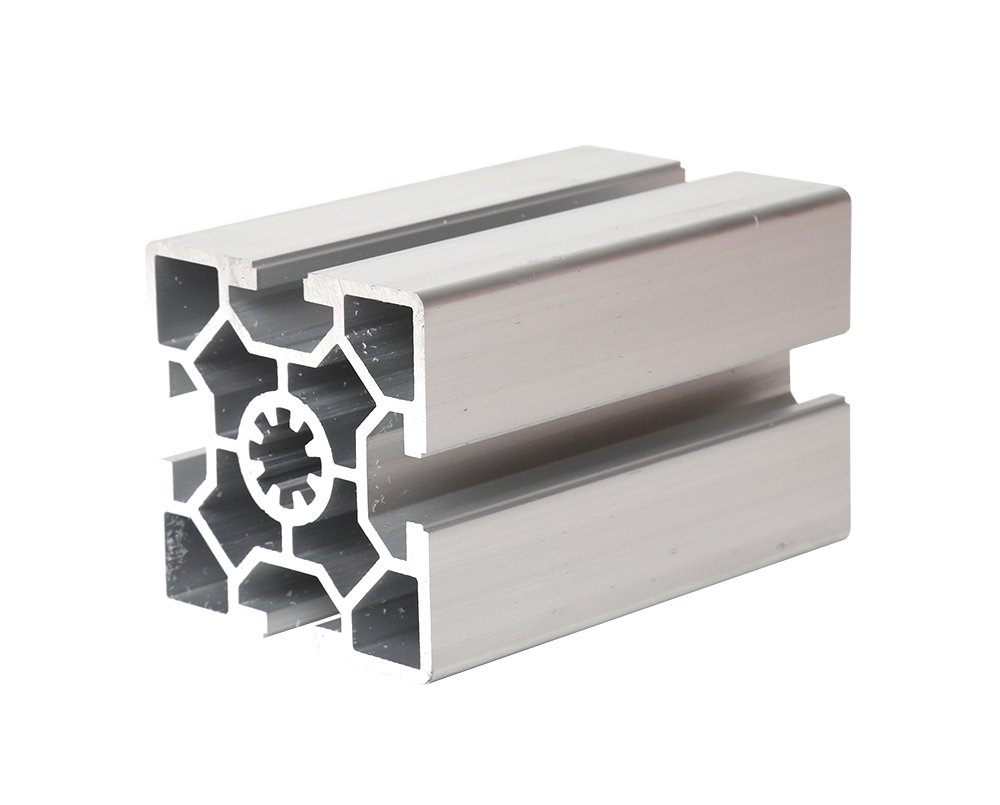

aluminium sliding door profiles

Choose aluminum alloy die-casting with the spirit of craftsmanship

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible