The service life of die casting molds—critical assets in high-volume manufacturing—depends on material selection, design, operating conditions, and maintenance practices. A well-maintained mold can produce hundreds of thousands to millions of parts, ...

The design and manufacturing of die casting molds are critical to the success of aluminum alloy die casting, as they directly influence part quality, production efficiency, and mold lifespan. This process requires a blend of engineering precision, ma...

Aluminum die-casting plays a pivotal role in producing hardware tool accessories, balancing durability, cost-effectiveness, and functional versatility. Hardware applications often prioritize aluminum alloys like A380 and A386 for their high strength-...

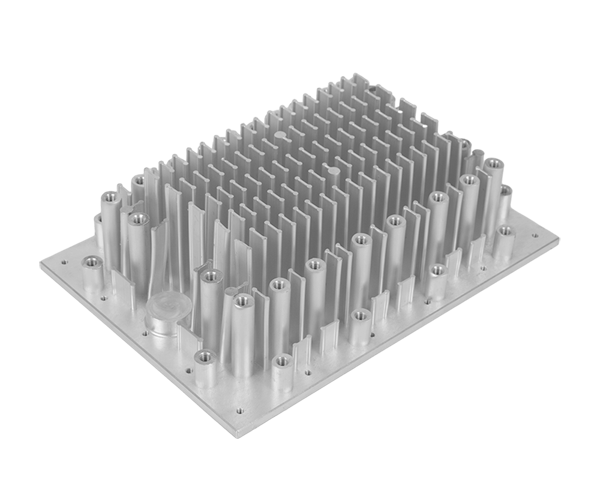

The 3C (computers, communications, consumer electronics) industry relies heavily on aluminum die-casting for structural components, driven by the need for lightweight, aesthetically pleasing, and mechanically robust parts. Aluminum alloys such as ADC...

The quality of castings is influenced by a complex interplay of material, process, and equipment factors, each critical to achieving desired mechanical properties, dimensional accuracy, and surface finish. Material-related factors are foundational: t...

Die casting aluminum parts are widely used across various industries due to their excellent combination of lightweight, high strength, and cost-effectiveness. In the automotive industry, they are integral to manufacturing components such as engine br...

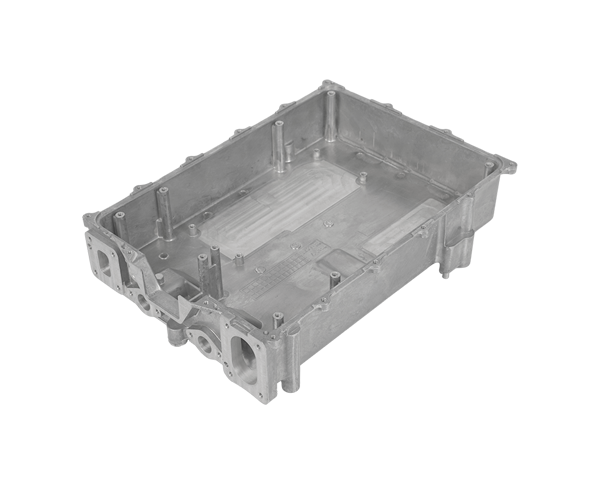

Pure aluminum die casting has found extensive applications in the field of communication equipment, playing a vital role in enhancing the performance, reliability, and functionality of various devices. The unique properties of pure aluminum, includin...

Creating pure aluminum die - casting handicrafts requires a combination of technical skills and artistic creativity. The unique characteristics of pure aluminum, such as its bright luster, malleability, and ability to hold fine details, make it an id...

Aluminum castings have become indispensable in new energy vehicles (NEVs), serving as foundational components that enable the lightweighting, efficiency, and structural performance required for electric and hybrid propulsion systems. As NEVs prio...

High-end artistic works, including sculptural elements, decorative artifacts, and limited-edition art pieces, leverage alloy die casting to transform creative visions into tangible, durable art. This method allows artists and designers to realize...

Rehabilitation medical equipment, including wheelchairs, orthopedic braces, and physical therapy machines, relies on alloy die casting to balance strength, weight, and cost-effectiveness. These devices often require load-bearing components that c...

Aluminum Alloy Die Casting for Security Monitoring Enclosures In the realm of security monitoring, the reliability and durability of equipment are of utmost importance, and aluminum alloy die casting has become a go - to solution for manufacturing...

Aluminum Alloy Die Casting in Smart Door Locks Smart door locks represent the convergence of advanced technology and security, and aluminum alloy die casting plays a pivotal role in their manufacturing. These locks incorporate electronic component...

Precision aluminum die casting is a highly specialized process that demands strict control over dimensional accuracy, surface finish, and material properties. In the surveillance and security industry, where components must integrate seamlessly w...

Does Die Casting Require Mold Opening First? Yes, die casting inherently requires the use of a pre-fabricated mold (die), and the process begins with mold preparation. The mold is a critical component of die casting, as it determines the shape, si...

Choosing the right alloy for die casting depends on the part’s functional requirements, such as strength, heat resistance, corrosion resistance, and cost. The most commonly used alloys in die casting include aluminum, zinc, magnesium, and copper-...

Zinc alloy die castings are valued for their versatility, excellent castability, and balanced mechanical properties, making them indispensable in numerous industries. Their applications span from consumer products to industrial components, leveragi...

Zinc alloy die casting typically has a density ranging from approximately 6.6 to 7.2 grams per cubic centimeter (g/cm³), depending on the specific alloy composition. This density is higher than that of aluminum alloys (2.5–2.8 g/cm³) but lower th...

Die Casting of Aluminum Alloy Subframe The die casting of aluminum alloy subframes has become increasingly popular in the automotive industry due to the material's excellent properties and the process's ability to produce complex, lightweight comp...

Melting Process of Die Casting Zinc Alloy The melting process of die casting zinc alloy is a critical stage that directly impacts the quality and performance of the final cast parts. It involves several steps and requires careful control of variou...