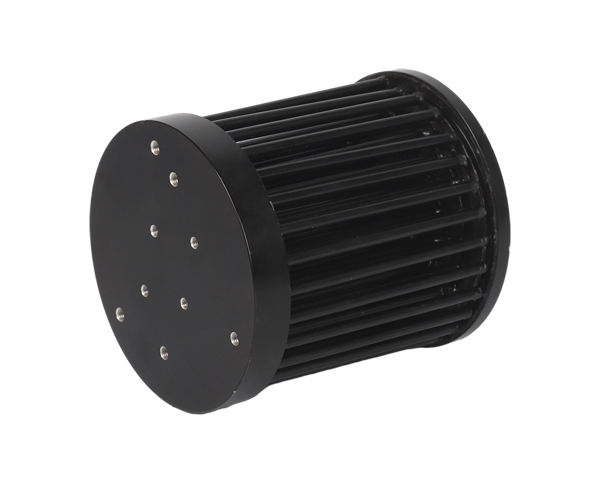

LED lighting systems—from industrial high-bay lights and commercial downlights to residential bulbs and automotive headlights—rely heavily on effective heat dissipation to maintain performance, longevity, and light quality. Unlike traditional incande...

Heat exchangers—devices that transfer heat between two or more fluids (liquids, gases, or a combination) without mixing them—are essential in industries such as HVAC, automotive, power generation, and refrigeration. Die-casting has become a key manuf...

Die-cast aluminum parts are ubiquitous in household appliances, valued for their durability, versatility, and cost-effectiveness. These components, used in everything from kitchen appliances (refrigerators, ovens, blenders) to laundry machines and ai...

Volume compensation design is a critical aspect in die casting engineering, aimed at addressing dimensional changes caused by solidification shrinkage, thermal contraction, and residual stresses during the manufacturing process. This design strategy ...

Dimensional and geometric tolerance control is a vital aspect of die casting quality management, ensuring that cast parts meet precise dimensional requirements and geometric specifications. This control is critical for ensuring part interchangeabilit...

Multi-cavity die casting solutions are advanced manufacturing approaches designed to produce multiple identical or similar components simultaneously in a single die, significantly enhancing production efficiency and reducing unit costs. This techniqu...

Alloy hot cracking is a common defect in die casting, occurring during the solidification phase when the alloy is in a semi-solid state, characterized by brittle cracks that form due to tensile stresses exceeding the material’s ductility. This issue ...

Hollow structure design in die castings involves creating internal voids or hollow sections within a cast part to achieve weight reduction, improve thermal efficiency, enhance structural performance, or accommodate other components. This design appro...

Ultrasonic crack analysis is a non-destructive testing (NDT) technique widely used to detect and evaluate cracks in die-cast components, leveraging high-frequency sound waves to identify internal and surface defects that may not be visible to the nak...

The ejection process in die casting is a critical stage that involves removing the solidified part from the die cavity after casting, requiring precise control to prevent part damage, ensure production efficiency, and maintain die longevity. A well-d...

The riser system in die casting is a crucial component designed to provide a reservoir of molten metal that feeds the casting as it solidifies, preventing shrinkage defects and ensuring the integrity of the final part. A well-designed riser system co...

Die casting machine maintenance and servicing are essential practices to ensure consistent performance, extend equipment lifespan, and minimize unplanned downtime in high-pressure die casting operations. Given the harsh operating conditions—high temp...

Heat treatment of die castings is a post-processing operation used to enhance the mechanical properties—such as strength, hardness, and ductility—of cast parts, as well as to relieve internal stresses induced during the casting process. This is parti...

The support structure in die casting is a critical design element that provides stability to the mold and the casting during the manufacturing process, ensuring dimensional accuracy, reducing warpage, and preventing damage to both the mold and the pa...

Density control is a critical aspect of die casting production, as it directly impacts the mechanical properties, structural integrity, and performance of the final components. Density, defined as mass per unit volume, is influenced by material compo...

Alloy die casting plays a vital role in the production of high-performance fishing tackle accessories, meeting the stringent demands of anglers and the harsh marine environments these accessories encounter. Fishing tackle, including reel bodies, lure...

Die-casting plays a pivotal role in the production of electric vehicle (EV) parts, offering a cost-effective and efficient method to manufacture lightweight, high-strength components that meet the stringent performance requirements of electric mobili...

Die-casting engine casing is a sophisticated manufacturing process that produces robust, complex housings for internal combustion engines and electric motor assemblies. Engine casings serve as structural components that protect internal parts, contai...

A drone antenna controller is a critical component that manages and optimizes the performance of antennas mounted on unmanned aerial vehicles (UAVs), ensuring reliable communication, navigation, and data transmission between the drone and its ground ...

A flow meter sensor antenna is a specialized component designed to enable wireless communication between flow meters and data collection systems, facilitating remote monitoring and transmission of flow rate, volume, and pressure data. Flow meters are...