Alloy die casting has revolutionized the production of garden tools, offering a perfect blend of durability, precision, and cost-effectiveness. Garden tools such as pruning shears, hedge trimmers, shovel handles, and lawnmower components often requir...

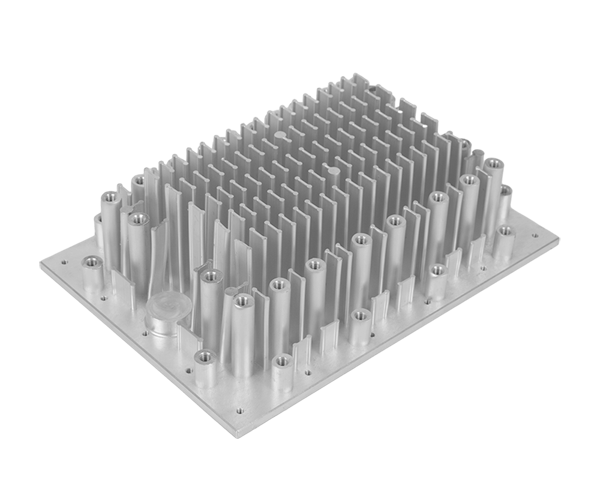

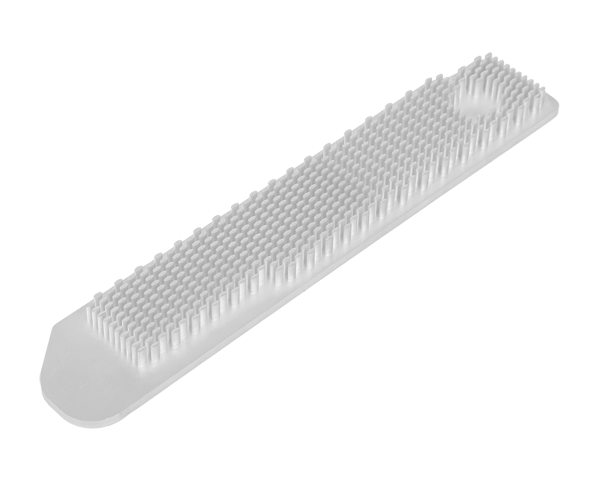

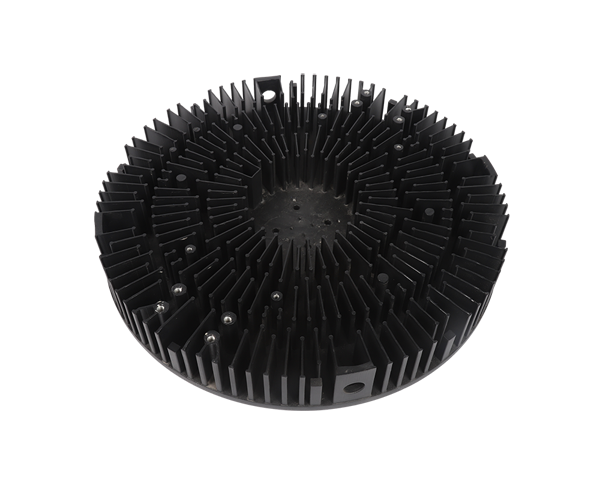

Die-casting radiator processing is a specialized manufacturing technique that produces high-performance heat-dissipating components for automotive, industrial, and electronic applications. Radiators require complex geometries with thin walls, intrica...

Die-casting aluminum automotive wheel hubs is a specialized manufacturing process that produces lightweight, durable wheel components critical for vehicle performance, safety, and fuel efficiency. Wheel hubs connect the wheel to the vehicle’s axle, t...

Electroplating aluminum die castings offers a multitude of benefits that enhance their performance, durability, and aesthetic appeal, making the process indispensable in industries ranging from automotive to consumer electronics. Aluminum die casting...

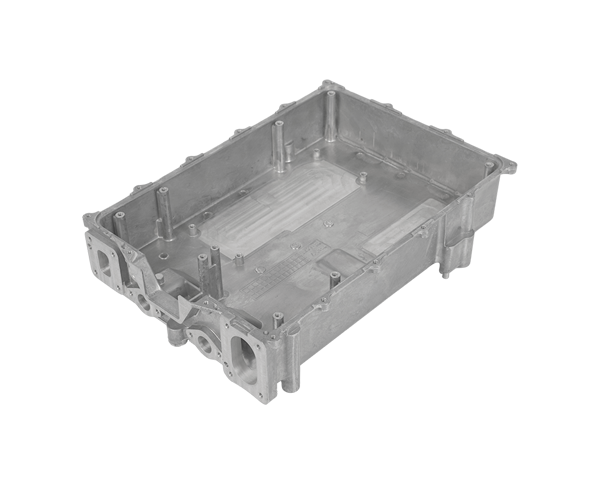

Die-cast fire-fighting accessory housings play a critical role in ensuring the reliability and durability of fire protection equipment. These housings, typically made from aluminum or zinc alloys, are designed to enclose and protect essential compone...

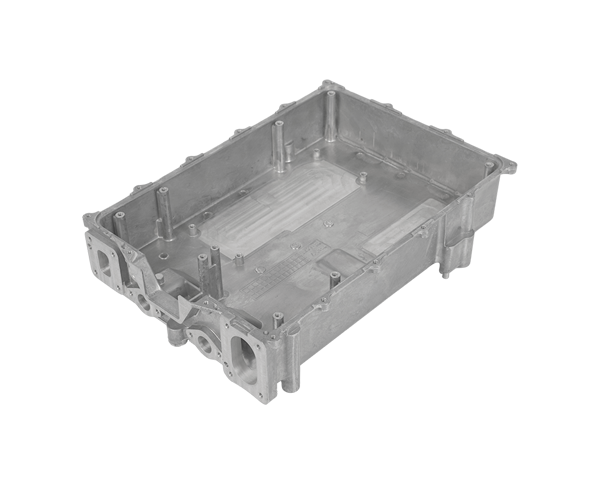

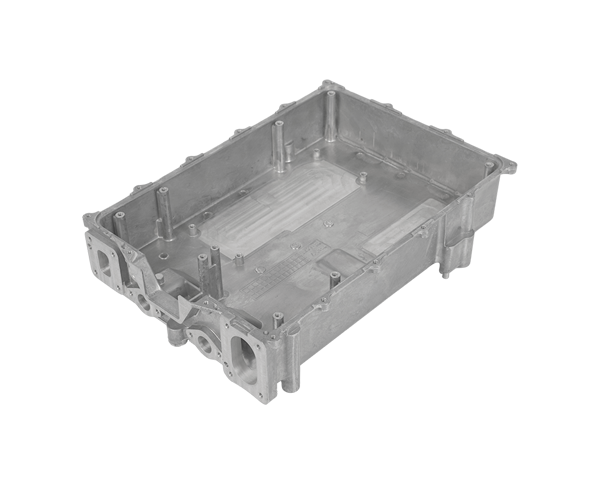

Magnesium alloy die-cast enclosures have gained prominence in industries ranging from electronics to automotive due to their unique combination of mechanical, physical, and economic benefits. One of the most significant advantages is their exceptiona...